The little Wittman Tailwind is

too often ignored, when it comes to talking about viable homebuilt

projects. Everything said in the following (except the prices) are

as valid today as they were 35 years ago. The Tailwind is still one

of the most efficient, cost-effective airplanes ever designed and

more folks should be building them.

Before there was an FAA, Steve Wittman was out “there” going

fast. Before there were jet aircraft, there was the old master — going

fast. Belore there were P-51s and P-40's, there was the Oshkosh wizard — you

guessed it — going fast. In fact, just about the only thing

in aviation that predates Steve Wittman is…well… not

a heck of a lot of anything of any importance and most of that had

to do with the Wright brothers!

Steve built his first airplane early in the Depression and there are

still a reasonable number of pilots who can claim to have been part

of that pioneering era. A few of them even raced with Steve and maybe

even beat him. How many of that era, however, can lay claim to having

recently flown an aerobatic airshow at Oshkosh while in their mid-80s

and how many are still running efficiency races in a single -place

racer. and which of them still flies a high-speed commuter plane,

which he designed and built. from Oshkosh to a winter home in Ocala.

Florida? Also. how many of them announced a few months ago, at

the age of 87, they were getting remarried?

Steve Wittman was. is. and always will be, a legend!

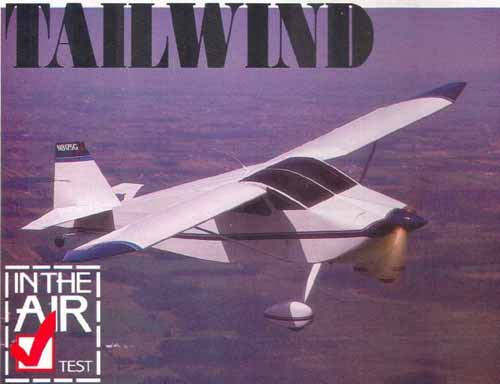

In this day of flowing, super-slick glass airplanes. it's easy to look

at most of Wittman's designs and say they look crude. As far as that

goes, when they were brand-new most of them looked a little on the

crude side compared to any of the supposedly more streamlined designs.

However, to make that comparison, one has to ignore the absolute test

of aerodynamics which boils down to how fast does it go, how far will

it go. and how does it handle? Judged by those standards, his airplanes

always blew factory-made machines into the weeds. It was only with

the advent of the composite kits that anyone, including the homebuilder,

was capable of building an airplane with more speed and range per horsepower.

Yes. on the same engine, a Lancair, for instance, is faster than a

Tailwind and. yes. a Glasair can run away and hide from most of Witt’s

designs. Just for the hey of it, however, let's throw in one more standard

to be used in measuring his designs: Cost. There aren't too many absolutes

in aviation, but one of them follows: No aircraft designer in history

has consistently squeezed more speed out of a buck than Steve Wittman.

End of conversation. All of his designs were bargain-basement bullets

that. while they may not have been as pretty as the rest, are still

untouchable when it comes to going fast on a budget — which includes

both operating and building costs.

In 1953. when the EAA was just a bunch of guys in plaid flannel shirts

who hung around Poberezny's basement, Wittman decided to design and

offer plans for a little two-place airplane that drew on his most

recent experiences of campaigning his Goodyear

(now Formula I) racers, as well as his innovative little two-placer

named Buttercup. The Goodyear equation involved taking the then-super-common,

190-inch. 85 horse Continental and mating it to a pair of Hershey bar

wings totaling no more than 66 square feet of wing area. For his new

airplane, the Tailwind, he increased that to a whopping 91) square

feet (a Cub is 178 square feet).

Wanting the most speed possible out of the power available — while

carrying two people — he minimized the flight deck but not so

much as to make it uncomfortable. Anyone who believes that Wittman

designs are too small for normal sized people have to remember Steve

himself is nearly 6 ft. 3 in. although he has never been much wider

than a fence post.

One of the problems of any side-opening. stick-controlled airplane

has allways been threading your legs around the sticks while entering

or exiting. Steve poked holes in that problem by using a centrally

stick with inverted-shaped extensions, giving each pilot his own control

stick without having to climb over or around. Although narrow by Spartan

Executive and Staggerwing standards. the original W-8 Tailwind cabin

was suprisingl-y comfortable given its cubic layout and rather

basic furnishings. Even more important, the visibility over and

around the nose is much better than would be expected for a tailwheel

airplane regardless of its size. Also helping the visibility is

the characteristic cutout in the leading edge of the wings. where it

intersects the flat wrap windshield.

When examined visually, not many secrets are showing, but the airfoil

shape of the fuselage is obvious. This is one of Sieve's secrets: You

can get by with smaller wings, if your fuselage is helping to lift

its own weight, rather than simply being a convenient place to hide

passengers and mount wings. What appears to be a study in straight

lines is actually an interesting exercise in fooling the wind into

thinking it is working with a much more sophisticated shape. The way

the wings bleed into the highly raked windshield and how the windshield

disappears into the cowling lets the passing wind part smoothly, generating

as little drag as possible with as simple a shape as possible.

It is the simplicity of shape that lends the airplane so nicely to

amateur building. That same simplicity combines with a similar

simplicity in structure to camouflage several basic rules that cannot

be violated in Tailwind construction. Number one rule is keep it light— little

wings don't need extra weight. The second rule is keep it clean.

These rules mean building everything as straight and as close to the

plans as possible. An airplane that gets all its performance from

aerodynamics rather than horsepower won't tolerate sloppy building,

which is one reason Tailwinds with similar engines often have speed

variations of as much as 20 mph from one airplane to the other. Also,

some owners lie more than other.

The landing gear of the Tailwind represents the one and only area in

which Steve broke entirely new ground in its design. Steve can lay

claim to two different major patents in landing gear design: The flat

gear, the called “Cessna” spring gear and the other being

the tapered rod "Wittman" gear as used on the Tailwind (and

the Buttercup before it). Although not actually as simple to make in

a garage as it appears, the gear is wildly effective and downright

clever in the way its twisting and spring action actually aid the gear

geometry and help keep an airplane straight on the ground. The

landing gear legs, which plug into two sockets in the fuselage, fortunately

are one of the items still readily available in a pre-fabricated.

ready-to-plug-in kit from many suppliers at a reasonable cost.

The rest of the airplane is down and dirty 1930, in concept, but with

a weight-watcher thought pattern tossed in. The fuselage is steel tube

with an absolute minimum of either sheet metal or stringers, so the

usual myriad of tabs and standoffs associated with steel tube are absent.

The wings arc tiny little plywood-covered units utilizing a sheet of

ply wood per side so there is none of the tedious scarfing and joining

which is often the case, when a wing exceeds the all-critical 4x8 dimension.

There aren't many airplanes whose airframes can be built as cheaply

as the Tail-wind. Although rag and tube is a labor-intensive medium.

that has to be weighed against the ability to put together a complete

airframe minus engine and propeller for something under $5,000 (Ed

Note from 2008: It’s still not too far from that). If a

little scrounging is done and the builder substitutes his elbow

grease for the cost of pre-fabricated components, there is every reason

to believe an airframe could be fabricated for less than $4000 (I’d

be afraid to hazard a guess today. Maybe $5,500?).

Naturally. the choice of engines is going to drastically alter

the overall cost of the airplane. but that's definitely a known number

the builder can control and it can range from anywhere from the $5000

category for a lucky find on a mid-time 0-200 up to $12-$15,000 on

a freshly overhauled 150 Lycoming.

The bottom line cost on a Tailwind depends on how much scrounging

is done, how fancy all that electrical stuff gets and whether the finish

is a killer ten-point shiner. Cost is probably going to bottom out

at $12.000, but can run as high as $25,000 (add about 40% to that

today). There have been many Tailwinds built far out on either

end of this range. but in todays enviroment these numbers seem realistic.

From almost the minute the airplane was introduced in 1953. homebuilders

began interpreting the design with their way of thinking. Originally..

this was limited to paint jobs and tail shapes, but by the late ‘60’s

it became the basis for aerial hot rodding that sometimes reached

the ridiculous. These mods included airplanes with as much as 210 hp,

a constant-speed prop and at least one with a neatly designed retractable

gear. Witman's "simplicity" philosophy has yielded to

the demand or more horsepower and other consumer-oriented mods including

a short-lived noscwheel conycrsion.

Naturally. the trigear Witt put on his own airplane was simple and

light, being the tapered rod, full-swiveling type. Although, it worked

fine, he is often quoted as saying he was never truly comfortable

with the unit since it was like having a sword hanging over his head.

He knew if the engine quit and he had to put put it into arough held,

that nose gear strut was going to come jabbing up in his general

direction — something which didn't make him all that happy — so

he quickly removed the offending item.

Another Wittman mod utilized the little 215-inch aluminum engine V8’s

that were used in Oldsmobile F-85s of the early 1960s, Wittman side-stepped

the usual gearbox, which designers utilize auto conversions to keep

the engine turning fast and the prop turning slow. Instead, he turned

the engine backwards and put the fly wheel in front, bolted on

an extension and prop. and simply let the unit turn as fast as

he thought it could without driving the tips supersonic. Utilizing

his own propeller design, he felt he was able to pull an honest 155-160

horsepower with no major modifications to the engine other than replacing

the original 215 crank with the longer stroke 300-inch unit. From

the outside, you would never know it was a liquid-cooled engine, since

he kept the radiator entirely within the engine cowling where it cooled

beautifully. Although only a small number of aircraft have been built

using that engine, they have. almost without exception, performed flawlessly.

In the late 1960s, Steve opted to update the airplane to W-10, which

included tapered wingtips. These reportedly add significantly to the

speed while lowering the stall, which allows slower landings.

The average C-90/0-200 W-8 Tailwind is going to weigh in the 700-720

pound range, but those insisting on slick finishes, plush interiors

and full panels, add perhaps as much as another 75 pounds. The 150

horse Lycoming airplanes should be in the general neighborhood of 750-800

pounds, while the six-cylinder 145 horse Continental adds another

15 pounds.

Wittman has often been quoted as saying he considers the very

best combination to be a light airframe with a six-cylinder 145 horse

Continental because even though it does add just a little more weight

it is, in his words. "so smooth.”

Given all the numbers, there is always the big question on how the

Tailwind actually flies. We could cut this treatise really short

by saying it flies fast, is fun and is absolutely beautiful in

almost all regimes. A few specifics, however, might he helpful.

Sitting on the runway. the first things a new Tailwind pilot will notice

are the feeling of sitting quite far back in the airplane (which

he is) and visibility is a little short off to the sides. By moving

the nose around a little bit. he'll see most of the pattern with little

or no turning. and the visibility through the cabin top, while not

up there with a Mustang bubble canopy, it comes close.

As the power is brought up on takeoff, the initial feeling is going

to depend on how many horses are crowded into the cowling. The small-engine

airplanes are going to give what initially feels like fairly spirited

performance as it starts rolling. The big-engine airplanes get

with the program in no uncertain terms and will out-accelerate

just about any Wichita Spamcan. The small-engine airplanes suffer severely

from having too much prop to let the engine really turn up on takeoff.

This is a common problem with any airplane that has the wide speed

range presented by the Tailwind. To go fast at cruise requires a prop

with an entirely different pitch than it wants at takeoff to let it

turn up. For that reason, the airplane will get off the ground reasonably

quickly but has to be left nose low for a second or two to let the

speed build while the engine. is working up the horsepower to climb

The big-engine airplanes have a little more ad-vantage since they can

put more horsepower out into the slipstream, even with coarse pitch

props.

Almost as soon as the airplane is rolling. the weird shape of

the sticks is no longer noticed and only the overall quickness

of the airplane remains. Again, depending on the weight and horsepower,

the rate of climb will vary somewhere between 600 and 1000 feet per

minute, and the pitch stability is solid enough that it holds trim-speed

much better than first-time pilots anticipate. All first-time

Tailwind pilots assume the airplane is going to be wildly twitchy

on all axis, which it simply is not. If the pilot were to close his

eyes, almost everything about the airplane would tell him he was flying

an early Yankee — possibly an AA-IA.

Once the nose is pushed level and the airplane is allowed to build

up cruise speed, the small-engine airplane should he trueing somewhere

in the 150 mph category, while those with the bigger engine and all

the later mods are trueing an honest 190 mph at altitude. In reality,

most 150 Tail-winds cruise at 160 or 165, but at Oshkosh '91 many W-10.s

with 145 horse Continentals were so straight and clean and had

so many fairings and speed tricks that owners swore 185-190 mph was

a perfectly real number at cruise.

Although the airplane is a long way from being a Cessna 210 in the

overall handling and ride category, it is noticeably better than

the aforementioned American Yankee. When the power is brought back,

the stall characteristics are also reminiscent of the Yankee. Again,

depending on the air-\plane. as it is crowded into the stall and held

there. the break has a very slightly sharp edge and it may roll slightly

in one direction or the other depending on how straight this particular

builder got his rigging. The stall will happen around 55 mph and is

coming down at a pretty fair rate of descent at that point.

Something worth playing with in the airplane is to start yanking and

banking, putting some hard corners onto the machine and see what

G does to its speed. As with all low-aspect ratio wings, it doesn't

take a very hard pull to burn off a fair amount of speed. This is especially

true when setting up for an approach. A ham-fisted pilot could

burn off more speed than desired through his own negligence.

Flying the approach is easier than in almost any Cessna or Piper if

nothing else, because the airplane is loaded just a little heavier

and penetrates through the turbulence that much better, drawing

a perfectly straight line for the intended point of touchdown.

The approach speeds may vary between 80-90 mph depending on the weight,

but at no point is it anything unusual, and once again the Yankee

comes into mind. At no time during round out and flare does the runway

disappear, and it isn't until the tail is well down that any part of

the runway disappears.

As a three-point attitude is approached, it is impossible to see directly

over the nose and it is necessary to concentrate on one side of the

runway to keep the airplane straight. If the airplane touches down

straight, the rollout can almost be boring. If the airplane is put

down slightly crooked. that marvelous tapered rod gear will shake and

shimmy a little bit as the airplane asks you to do your bit in getting

the tail hack where it is supposed to be. It is no more demanding than

a Citabria but things are happening much faster and give the illusion

of being a more demanding airplane. If the pilot is a little slow in

keeping things straight, the plane does not turn around and bite him

as many other tailwheel airplanes would.

There have been many two-place homebuilts designed in the last 40 years

and. as we come into the new century, they are getting more sophisticated

and expensive. Composites may require a shorter learning curve to master

the building skills, but because of many of their systems and the speed

at which they travel, they require more attention both in maintenance

and in proficiency.

The Tailwind is a machine that may not be quite as fast and as sexy

as some of the new airplanes, but how many of the new airplanes would

be as fast as they are with the gear down? And how much does the landing

gear alone contribute to cost and complexity.' If all things are

taken into account, the extra 20 or 30 mph in cruise can easily be

looked at as being unnecessary in light of the inspired simplicity

represented by the Tailwind — it is a hammer meant to drive a

specific nail by a specific type of carpenter. And it does that

job about as well as any airplane ever designed, with a lot less effort,

expense, and power.

The Tailwind is one of the seeds that helped give birth to homebuilding.

With any luck, it is going to be with us for another 40 years as another

new generation of homebuilders realizes two-place airplanes don't have

to cost $50.000. BD

For lots more pilot

reports like this one go to PILOT

REPORTS

|