|

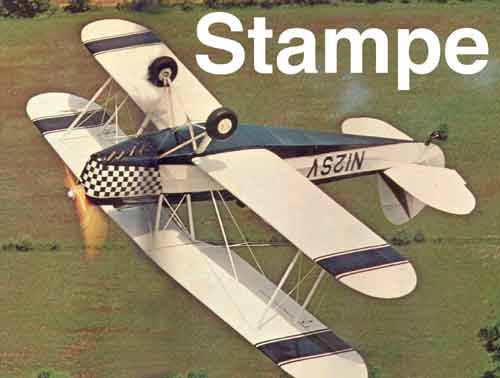

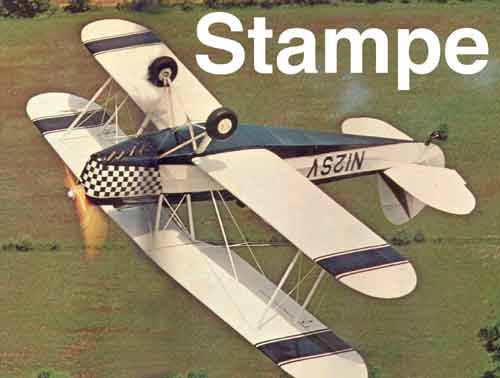

The Wooden Wonder |

The latest entry in the build-it-in-your-garage field of old biplanes is the SV Stampe (pronounced "Stomp," or so I'm told). The Stampe is a Cub-common French primary and aerobatic trainer that, although it pre-dates World War II, was still being produced in the late 1950s. Everybody who is anybody in Europe has buzzed at least one village green while cavorting in his Stampe. But I had never even seen one.

In Trade-A-Plane, I

noticed an ad for Stampes; the area code for Touraine Aero was Pennsylvania,

not far from my stomping grounds, so I gave a call. In answer to my

question about having any Stampes, Tony Tirri said they had 14 of them. If you're in doubt as to the Stampe's structure, Labate's hangar is the place to go learn about it, because there are skinned Stampes all over the place. It seems Labate and Tirri either bought a winery that used to be a licensed Stampe factory, or else a grape crusher used to make Stampes, or SV decided to make wine in this particular factory, or something like that. Anyway, they ended up with all sorts of templates, drawings, production jigs and a shipload of disassembled Stampes and parts.

I singled out one particularly nude-looking fuselage and looked at it as if I were thinking about buying it (by this time, I was). I was more than surprised to see that the pieces aren't glued and nailed together at all; they are "crushed" together. Each vertical spruce member is fitted into a little steel cap that has ears on it. The ears pick up tension wires that are connected to other steel caps on other spruce members. When these wires are pulled up tight, they pull down on the caps, putting the spruce in compression, in effect "crushing" the little caps on. In the aft fuselage, there is no wood-to-wood contact, and the forward fuselage has conventional plywood and stringer construction. I was no longer afraid of the wood fuselage. The rest of the airplane is of normal wood-and-fabric construction. The landing gear is the only unique feature: It has a big streamlined tube filled with streamlined rubber doughnuts that compress on landing. It looks as if the Mooney landing gear has French ancestry.

The engines are 145-hp Renault in-line fours with inverted systems and air starters. These airstarters pressurize all four cylinders in sequence, rather than just working on one hole as some airstarters do. A tiny engine-driven pump pressurizes a bottle aft of the cockpits so you don't have to keep constantly refilling the system.

|