WE WERE SKIMMING along on top of a 4500-foot broken deck, enjoying the sensation of speed as the tops of the puffies ripped past us. Then I saw him out in front through a break in the deck. The range was probably 3 miles but the V-tail shape was unmistakable. What was even more unmistakable was how rapidly my rear-end view of the Beech Bonanza was getting bigger. When we caught up with him and he disappeared under our wing, it seemed as if less than a minute or so had gone past. It was obvious that we had an easy 35- or 45-knot advantage over him.

I glanced over at the engine instruments and saw we were pulling about 2350 rpm and 23 inches Hg of manifold pressure and were indicating 215 knots. I don't know if the Bonanza ever saw us, as we were above the clouds, but it would have been disappointing for him to look up and see our rotund shape disappear from sight in a depressingly short period of time. Bonanzas are no slouches as cross-country airplanes but the Questair Venture eats airplanes like Bonanzas and Cessna 210s for lunch (no cracks about it looking as if it hasn't digested one yet).

This was my third evaluation flight in the Venture over the last couple of years and every time I hop into it, I come to like it more and more. More than that, I've come to respect not only the airplane's performance but the professionalism of the team behind it. The Venture is unique in a lot of ways and deserves some close examination.

If you're reading this magazine, in all probability you're doing so because you look at airplanes in a slightly different vein than the average EAA/homebuilt type. An airplane to you is a piece of transportation to get from here to there as quickly and efficiently as possible. You are long on utility and short on patience. That, in a nutshell, sums up the mission for which the Venture was designed. It was designed to fly high, get there fast and ignore the weather.

For an airplane to be truly a serious cross-country airplane, it has to be able to go when the airliners go. Which means it has to be designed as if the sun never shines. It's an instrument platform first and a VFR traveling machine second. That, too, describes the Ven-ture. It is an extraordinarily serious, mission-specific cross-country hummer.

Ignoring the fact that everyone picks on the Venture's looks, if it suffers from anything within the private pilot community, it would have to be that it falls under the category of homebuilt. The nonsport aviation community has for years been laboring under the miscon-ception that the majority of homebuilt airplanes are designed to flop around on a Sunday morning by someone in coveralls with butyrate under his fingernails. However, those more astute observers have noticed the top end of the homebuilt category has changed drastically. The new generation of kits is professionally designed, marketed and tested and offer utility far outside that available in factory-built Spam cans. Granted, in most cases, it is two-place utility as opposed to four-place utility, but every study ever done shows four-place airplanes spend most of their lives with the back seats vacant anyway.

Going hand in hand with the increased cross-country utilitarianism of the "new" homebuilts is the rapid improvement in kit construction and design. This has brought the kit airplane closer and closer to being a true snap-together machine that doesn't require a degree in engineering, a full machine shop or the rest of your life to construct. And everything that has just been said can be applied to the Questair Venture-in spades.

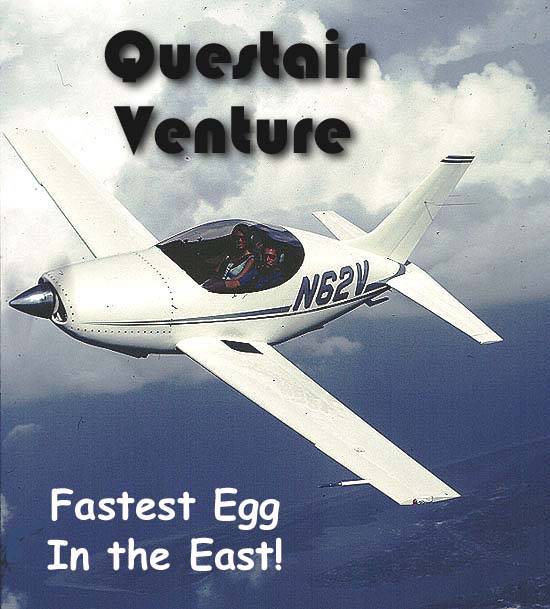

Unfortunately, aviation is notoriously dnven by looks and emotions-always has been, always will be. For that reason, when the Venture was introduced, the first comments heard were comedic monologues beginning with, "Look at it," and it was unceremoniously dubbed "The Egg." Even though the Venture has set some serious records, including 289 knots around a closed course for Class C-lb, there are still a lot of pilots who can't get past the looks. This is especially true considering its primary competition, the Glasair and Lancair, are sexy-looking machines, which helps sales a lot. Not to say both airplanes aren't faster than a civilian airplane has a right to be but the Venture is still capable of blowing past both of them. However, many in the market think the Venture looks like an egg on its tiptoes when parked next to either airplane. It suffers the same fate as the old AMC Pacer: Big on the inside, but small and, unfortunately, a little goinky on the outside.

The bottom line, however, is the airplane does what it is supposed to do and fits its mission as well as just about any airplane ever pro-duced, homebuilt or otherwise. Also, because it's made out of aluminum, you can park it anywhere and paint it any color your heart desires. You don't have the composite airplane problem of constantly worrying about the skin temperatures getting high enough that some day you come out to find a big, ugly puddle on the ramp where the airplane used to be.

Firewall

forward, the Continental 10-550 and McCauley propeller combination

is essentially a Piper Malibu QEC without the blower. Firewall

back, it could be said the airplane is a Malibu without the Malibu.

If the passenger cabin were whacked off that noted Piper speedster

and the tail glued to the flight-deck bulkhead, the result would

be something shaped an awful lot like the Venture. This is not

by accident.

Firewall

forward, the Continental 10-550 and McCauley propeller combination

is essentially a Piper Malibu QEC without the blower. Firewall

back, it could be said the airplane is a Malibu without the Malibu.

If the passenger cabin were whacked off that noted Piper speedster

and the tail glued to the flight-deck bulkhead, the result would

be something shaped an awful lot like the Venture. This is not

by accident.The design team for the Venture was Jim Griswold and Ed MacDonough, both Piper expatriates who had primary design duties on the Malibu project, and Doug Griswold, who had been a member of General Dynamics' advanced fighter team. It's also not by accident that those compound curves on the Venture are not glass but good, old-fashioned aluminum. Being from the old school, it would have been hard for Griswold and MacDonough to use what they undoubtedly see as a yet-unproven construction medium. Besides, building it out of aluminum short circuits an awful lot of the questions about composite longevity.

The Venture kits are designed for assembly, not building. It's not an airplane project where the plans are stretched out on a sheet of alu-minum and the builder whips out his sharpest pair of tin snips to start whittling parts from scratch. When the top is popped off the Venture kit box, what the prospective builder is looking at is the result of some very professional planning and, in many cases, design and manufacturing work that is downright innovative.

The fuselage skins, which are obviously compound, are completed, stretch-formed components, requiring only minor trimming before drilling holes and popping clecos in place. It is difficult to describe the level of completion for all the parts. Ribs, stringers, bulkheads, you name it, are complete and almost ready to use. The critical assemblies, such as the spars, are already finished, riveted and ready to be installed. This puts the scarier operations, like wing-fitting alignment and drilling, in the hands of professionals. The importance of this kind of completion can't be underestimated. The first-time builder has his hands full enough without being haunted by fittings requiring such close tolerances that only a machine shop can accomplish them safely.

Much of the kit's precision and complete-ness is the product of the computer age of CAD/CAM (computer-aided design and manufacturing) engineering. The drawings are also the result of the CAD/CAM program The wildly detailed assembly manual takes every part and shows it not only as an individual component but also as part of an assembly, making it much easier to visualize what goes where.

A huge amount of thought has been given to helping the prospective builder assemble the airplane. This includes packing into each kit several hundred pounds of steel plate that has been cut to a given shape with appropriate holes punched so when the steel sheets are bolted together, they become assembly jigs. This little touch is really neat and saves a prodigious amount of time, while guaranteeing alignment of the part.

Setting up the jigging for any airplane, but especially an aluminum airplane, is the heart of the project and determines how straight the assemblies will be and, therefore, how well the airplane will fly. In so many other kits, building the jigs is an exercise in precision that can often add significantly to the amount of time required to build the airplane. Questair has looked at that problem and, through its computer, set up this jigging system so the builder practically has precision handed to him.

The airplane we were privileged to fly was not only a different airplane from the prototype but is the first of the kit-built machines. Actual-ly, it's not fair to call it purely a kit-built airplane as it was done by, and for, Don Godwin of Atlantic Aero, which also happens to call Greensboro, North Carolina, home, and is located on the same airport where Questair has its plant. Godwin has been very close to the Venture from the beginning and is one of the original supporters of the company. Even though his airplane was built from kit parts and was used to debug the kits themselves, it would be fair to say that this airplane is still one notch ahead of an actual kit-built airplane. It might be called a P0K, or proof-of-kit machine. Even though it was built from the kits it, too, has several things in it that have been changed in the kits-i.e., airplanes after Godwin's all have additional stringers in the wings to stiffen them.

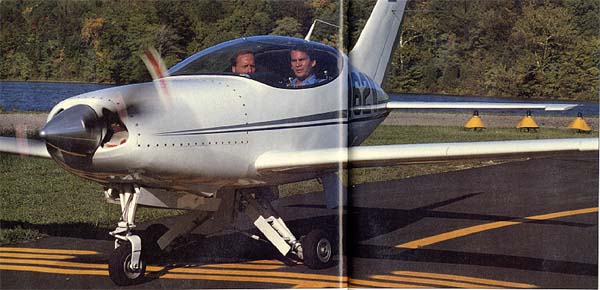

Stepping over the gunwhales of Godwin's airplane, I again emembered the comparison with the old AMC Pacer. For those of you who have for-gotten the easy-to-forget Pacer, it was an attempt by American Motors to produce a car that had the space of a regular car inside but was a compact car outside. The idea didn't work all that well for AMC but when applied to an airplane, it becomes an interesting concept. The result is a maximum inside and minimum outside.

The fuselage is wide, really wide, measuring 46 inches from side to side, which puts it right up there with the Beech Baron. However, not all that space is totally usable, as there is a console the size of a small ironing board running between the pilots that not only hides the landing gear but serves as a handy place to mount bunches of switches and such. Originally, the pitch trim was on the console under the throttle, but on Godwin s airplane, it has been moved over to the left control stick and is a standard two-part switch giving high and low rates, depending on whether one or both pieces are pushed. This is an important improvement over the original trim situation. The aileron trim is still a left-right rocker switch under your throttle hand that could stand to be relocated as it's possible to bump it accidentally.

The fishbowl canopy on the Venture is the subject of lots of debate among folks for a number of reasons. Among other things, it requires a strut nearly 3 feet long to hold it far enough open to allow pilot and passenger to crawl in behind it. Also, because once the canopy is closed the cockpit becomes a huge solarium, the extension strut has a stowage position that allows the canopy to ride a couple inches open. This allows heat to escape around the edges.

I crawled in next to Godwin and marveled at the size of the instrument panel, part of which is a perception caused by the fact that there are no control yokes which make part of it useless or invisible. In fact, there is neither control wheel nor stick in the normal sense of the word.

The Venture uses a unique control system in which the fore and aft columns that the control wheels would normally attach to have been relocated to the extreme outer edges of the panel, right up against the fuselage side. A hand-sized, L-shaped extension is attached to the end of the column, coming up 45 degrees from the fuselage sidewall. In this respect, it is almost a side stick, except it's not. It is, to my knowledge, the first time any such control system has been employed in an aircraft and it feels much more natural than it sounds.

Having flown the prototype before, I was forewarned about the importance of the seating position. It is critical that the pilot sit high enough to take complete advantage of the head-room; otherwise, he can't see over the long, dachshund-type snoot when coming in to land. With the seat back adjusted up about halfway, I felt as if visibility had improved a dozen fold and I still had several inches to go before hav-ing headroom problems. I'm FAA-average (5-feet 10-inches, 170 pounds), so the airplane should accommodate the tall pilot with no problem.

While I was strapping in, Godwin lit the fire under the big Continental and we started work-ing our way down the taxiway. It's necessary to talk about how the nosewheel steering and brakes work and it's absolutely necessary to understand the basic concepts when flying the airplane, as it's quite easy to misuse the brakes/steering and wind up with neither.

The nosewheel steering is activated by a horizontal hydraulic piston on the nose strut that valves pressure from both sides, depending on which peda1 is pushed. If only one pedal is pushed, the metering system puts pressure onto one side of the piston, causing the nosewheel to turn. If, however, both pedals are pushed, it somehow covers up both ports and converts that same hydraulic pressure to braking, leaving the nosewheel exactly where it was when the other pedal was pushed. When steering the airplane via the nosewheel, it's absolutely critical there be no residual pedal pressure left on the outside brake. Otherwise, the nosewheel steering doesn't want to work because it thinks it's supposed to be braking.

Encountering a new system such as this quickly points out basic piloting bad habits, which, in my case, appear to be a tendency to rest my feet on both brake pedals at the same time whether I'm turning or not. It took a fair amount of conscious thought to remember to lift the outside foot when making a turn, because even the slightest pressure screwed up the system.

The rudder pedals are not actually rudder pedals. They are a classic rudder-bar arrangement in which a horizontal bar is pivoted in the middle, the outer extremities of which are the actual rudder pedals. Theoretically, this means the pedals move in a circle around the center pivot. In actual fact, so little rudder movement is required that, if he weren't told, the pilot would think he was using normal rudder pedals. The toe brakes are mounted on the outer edges of the pivot arm and everything about it works very naturally.

As Godwin and I finished the runup, we went through what I consider to be one of the worse parts of the airplane's design-latching the canopy. There are three latches on each side, all of which must be latched securely by the pilot. This is necessary to pull the plexi-dome down snug onto its mating ring on the fuselage. The system works fairly well but it raises the question of, "What if you want to get out in a hurry?" Or better yet, "What if there's an emergency and a ground crew needs to get the pilots out in a hurry?" Nothing short of a fire ax is going to get through that canopy from the outside. The entire canopy setup is one that I've never liked. I'd much prefer to see it replaced with a fixed windshield and some type of swing-forward or gullwing hatch.

Out on the center line at St. Augustine's main runway, I screwed the power in slowly, being mindful of the fact that with more than 300 ponies in the nose, even a tricycle-gear airplane has a tendency to head for the left bushes. As the rudder doesn't become effective until it's rolling 20 or 25 knots, the new pilot is usually told to tap a little right brake then bottom the rudder, easing it up as necessary. Even though I'd been told to do that in the past, I always found it to be overkill. If power is brought in reasonably slowly and smoothly, the rudder gains effectiveness just as fast as the airplane gains speed, which is to say, mighty quick. As soon as you can feel wind in the rudder, the throttle can be squeezed on home leaving no doubt in your mind that this aircraft is able to get with the program. At the same time, the rudder alone is plenty to keep it on the more-or-less straight track.

On takeoff, this is an exciting airplane! How could it not be? No matter how slowly the power is brought in, it is impossible not to feel as if you're being launched down the runway by a catapult. Even at gross weight of 2000 pounds, its power-to-weight ratio is only 7.1 pounds per horsepower, which puts it in the category with a two-place Pitts Special. These are numbers most civilian pilots have never experienced and the net result is a pronounced adrenaline rush on the first takeoff.

The good news is that even though it's accelerating like a rifle bullet, the airplane will still let the pilot unload the nosewheel to run on the mains for a second before it launches itself into the air. I was surprised on my first takeoff to find that even though the runway lights were moving so fast they appeared to be 10 feet apart, I didn't feel behind the airplane. It's heavy enough, yet well enough balanced, that it let me know when the nosewheel was getting light and its long (as in really long) nose was hung out in front of me, making it easy to find an attitude reference.

As soon as the airplane is off the ground, if the gear is sucked up immediately, the first-time pilot is going to experience a slight tendency to fight the out-of-trim conditions presented by the changing drag of the landing gear. It's a better idea to wait a second and get some altitude, which literally takes only seconds. Once the gear is up, a quick decision has to be made as to whether the flight is going to be spent in the pattern or elsewhere. Otherwise, you'll find yourself past "elsewhere" while still trying to make up your mind. The airplane goes up so quickly that pattern altitude is generally violated before reaching the end of an 8000-foot runway like the one at St. Augustine.

The aileron trim is a little fast. Those long wings with their full-length fuel tanks require precision trim and the rate on Godwin's airplane was such that it was still too easy to over-shoot neutral.

As the nose is pushed down and the speed builds, the long snoot assumes a vaguely downward angle, essentially getting entirely out of the field of vision. At the speed we were moving, it initially takes a bit of careful attention to the instruments to set up a visual reference to aid in trimming to a given speed and altitude.

Breakout forces are reasonably light-in fact, for an airplane designed for instrument flying, they may be a little too light as it takes only the slightest wiggle of the wrist to effect any normal bank-angle change. However, in doing aileron rolls with this airplane, I found the pressures do build up at the extremes of travel and there is a good-sized perceived difference in control pressures when rolling the airplane to the left or right. This is because rolling it left with the controller in your left hand means you are trying to move your fore-arm in the wrong direction and it feels as if it takes more muscle, which is actually not the case. It's just that most of us don't have muscles working in that direction.

The airplane catches an awful lot of grief because people say it's too short to possibly be anything other than extremely sensitive in pitch. Obviously few, if any, of those folks have actually flown the airplane because in most normal flight regimes, there is no feeling of sensitivity in the elevator at all. Even though it is just a little bit loose in pitch stability in that it takes four or five cycles to damp out, it is still much better in that respect than many factory machines that are thought of as superior instrument airplanes.

A word about the airplane's stubby appearance: Aerodynamically, an airplane elevator arm is defined by multiples of mean aerodynamic chord (MAC). The rule-of-thumb range is generally 2.5-3.5 MAC. The Venture is at 3.0, which, although it is absolutely midrange, appears short because the wing's aspect ratio is so high, giving it a narrow chord. Take my word for it: In pitch, the airplane could be a Cessna 210.

It is quite deadbeat in yaw and interestingly enough, in moderate to severe turbulence, it rides the bumps quite well with no tendency to do any kind of Humpty Dumpty waltz like the Bonanza or a few others of its ilk. Also, because of its wing loading, it punches through a lot of moderate bumps, rather than riding over them. For that reason, it feels like a much heavier airplane, which is exactly what's needed in an instrument platform.

Having run speed tests in the past, I knew the 200+knot speeds we were seeing were real. I've timed the airplane at an effortless 235 knots at 75% or less, which is really hauling. One of the things that helps it mightly is it gets nearly 2 inches of ram-effect so it will hold 23 inches to nearly 10,000 feet.

I've always thought it was some sort of a testimony to the ability of modem homebuilt designers to have a speed envelope that ranges from 50-60 knots up to 220-230 knots and have an airplane that handles quite well at both ends of the spectrum. All of the modem superkits have quite good manners at the low end of the scale and the Venture is absolutely no different from the rest of them. With the power back and the nose up, whether the airplane is clean or dirty makes little or no difference. It wanders down to around 60 knots and leaves you sitting there with the control stick sucked up to your chest.

However, if you have the control stick nailed all the way back, you are doing it with two hands as there isn't one pilot in 10 who can easily pull it that far off trim and not screw up a shoulder muscle. Even when trimmed for an approach speed of 85 knots, it still takes two hands and a lot of time to get the airplane into a stall, which is just a classic mush with practically no break and only a gentle roll-off to the right (in Godwin's airplane, anyway). If as little as 12 inches of power is added, the airplane will continue climbing while the pilot has the stick hugged to his chest. This is not an airplane that is easy to stall accidentally.

One of the airplane's nicest features is its rather ungainly looking landing gear. What makes it so nice is it has an operating speed of 170 knots and lots and lots of flat-plate area and parasite drag. So if you want to come downhill from altitude, all that's necessary is to bring the power back, let that big prop flatten out to get rid of the first 50 knots. Then, throw the gear out, drop the nose and maintain 170 knots while coming downhill at 3000 fpm or better.

If the gear isn't dropped and the throttle is brought most of the way out, the airplane gets down to around 150 knots okay, but it's hard getting rid of any more speed without putting a lot of g on it. In fact, if you carry any power at all, you'll notice in the lower part of the speed regimes the speed almost exactly matches the manifold pressure. In other words, 15 inches gives 150 knots indi-cated; 16 inches, 160 knots. I sat there with 13 inches on the airplane, which is just enough to keep the cylinder head temperatures up, and went in an endless series of circles waiting for the airplane to slow down and it never did.

Dropping down to pattern altitude and get-ting the gear out before coming on to downwind, I once again reminded myself that the gear presents different amounts of flat-plate area depending on where it is in the extension cycle. At first, the nose wants to go up, then it wants to go down, then it stabilizes somewhere in between. It doesn't make any sense to attempt trimming before that because for seven or eight seconds, everything is changing.

Although it's probably not necessary to do so, once used to the airplane, I backed it out a fair amount before turning base so I wouldn't have to slip to get it to come down final. There is no opportunity to change glideslope by varying flaps because, when the gear comes out, the full-length ailerons droop, becoming full-length flaps at a given setting. What you get is what you got. However, the airplane is absolutely happy as a Cub to do great slips, even with the flaps out, which sometimes can come in pretty handy.

At 85 knots on final, the airplane is rock steady in every aspect and requires practically no attention to hold the speed, assuming it's trimmed correctly. From the time you turned final to the time you are ready to flare, the approach is quite anticlimactic, with one minor difference. Unless the final is miles long, there is no likelihood power will be needed. Those high-aspect ratio wings make the airplane into a glider. A normal C-2 10/Bonanza-sized approach will be flown absolutely power off with helicopter-style visibility.

As the airplane is slowed in the flare, the nose comes up at an increasingly steep angle until, as I was holding it off searching for the pavement with the mains, I might as well have been flying a taildragger for all I could see over the nose. It was no problem, however, to look out to the side, which in fact actually helped in gauging my height above the ground. On practically every landing I made, those big, long wings let me feel my way through ground effect so easily the mains clunked on in a way that made me reasonably satisfied with the touchdown. I hadn't made a fool of myself (for once).

One unusual thing about the airplane on touchdown is that the narrow gear and long wings let the airplane react quite noticeably to crosswinds or gusts. It will put a wing down and keep it there during a rollout or rock one way or the other on the gear. However, the ailerons are so effective that, as long as the airplane is moving, the wings can be kept level simply by asking them to be level.

It would be difficult not to be impressed by the airplane's handling and performance. It's not perfect, but few airplanes are. However, it is also a home-built airplane and, in that frame of reference, it is a phenomenal machine. It's also an airplane any competent Bonanza or Centurion owner can quickly and easily learn to fly

With the standard tankage of 56 gallons (85 gallons is optional), the airplane is good for 1000 nm. at maximum cruise of 240 knots. Read that carefully-that means the Venture covers that 1000 n.m. in a shade more than four hours! And, yes, it can take full fuel and two normal-size folks (useful load 760 pounds) along with baggage. As we said, it is a serious traveling machine.

Questair recognizes that the $65,000 base kit price for the airplane is a bunch and it's set up an interesting delivery program that breaks the scheduled payments into four different stages. If the entire kit is paid for at one time, the price is $63,000 and the funds are held in escrow until the kit is shipped within six months. Incidentally, the cost of the new Conti-nental IO-550-G engine and matching prop make up nearly half the kit price.

The high-performance homebuilt market is a fickle one and the success of the Venture hinges largely on the willingness of individuals who want an airplane for utility, rather than purely fun, to front that kind of money and to devote that kind of time. Questair said it is back-ordered into early next year, which indicates it is able to see a future that will keep the lights on. As the Venture is the only aluminum high-performance bird available (the Swearingen doesn't count, as it is no longer available), it at least has the "anti-composite" market to itself.

If one word of advice can be given to the prospective buyer/builder of a high-perfomance homebuilt kit, it is important he fly all of them. By doing so, he'll see that the Venture looks entirely different from the inside. Don't write it off just because its appearance isn't traditional. It may be an egg, but it is one hell of a fast egg!