Text by Budd Davisson, Sport Aviation, Feb, 2001, Photos: Jim Koepnick, EAA

| As is often the case, hombuilt kits come and go and it's highly possible that by the time you read this, the Lionheart may have gone. However, these kinds of manufacturing projects have a habit of bouncing back, so contact the EAA's Information folks to see if the kit is still in production. |

As I brought the throttle up on the Pratt & Whitney and that marvelous rumbling roar washed over me, I heard a small voice in my head say, "Hey, Bunkie, this is not the ideal situation to be test-flying an airplane for the first time, especially one as special as the Lionheart." Per usual, that little voice was given to understatement! I was going to be making my first takeoffs and landings in the Griffon Aerospace Lionheart in front of 100,000 critical spectators during EAA Air- Venture Oshkosh 2000. No pressure! And then there was the weather. It was dreary, low, and threatening rain. It was not uplifting to the soul. But, it had been that way all week. If I was going to fly the Lionheart, this was going to be it. Take it or leave it.

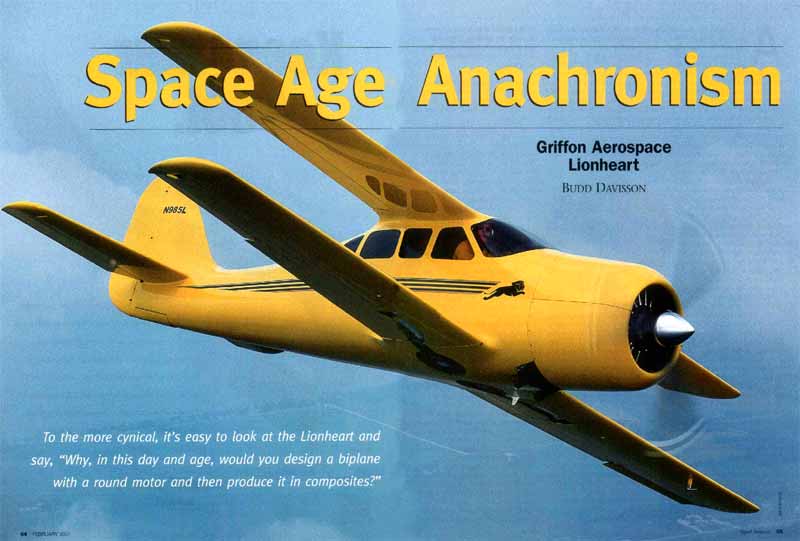

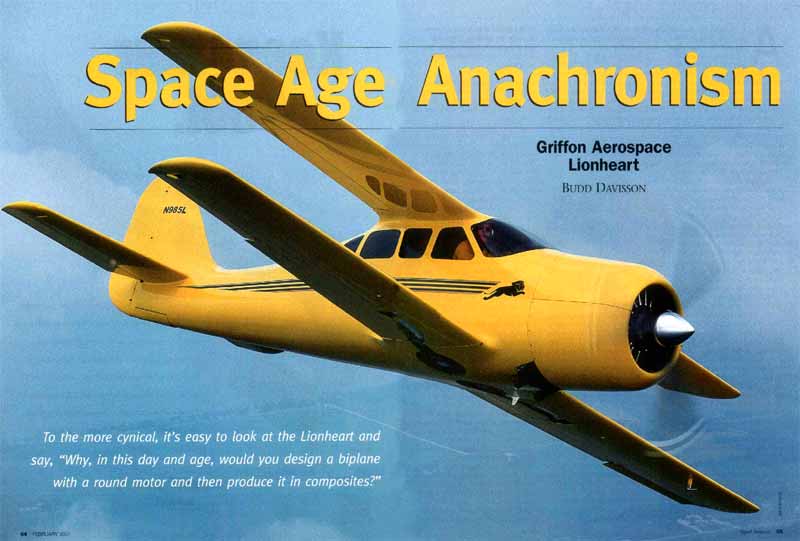

So as the airplane lunged ahead, I stared at the blurred edge of the runway, which was visible out my side of the airplane, and hugged the stick back, keeping the tailwheel nailed down until the elevators nudged the stick, letting me know they had plenty of air in them. The tail followed my hand as I pushed it gingerly forward, and I half expected the airplane to turn left if nothing else because of the gyroscopics of that big three-blade MT prop. The nose did nothing, however. It ran nearly rail straight, except for tiny little pressures here and there. Even better, as the tail came up, the visibility, which was actually pretty good in the tail-down position, became terrific. As we raced along on the main gear, I held a slightly tail-down position (which turned out to be extremely easy), letting the positive angle of attack dictate when the airplane was ready to fly. I wanted the takeoff to be a surprise, and it was. With no skipping or hesitation, the wings peeked over the lift curve, and just like that, we were airborne. I was finally getting to fly the Lionheart, one of the most unusual, most ambitious, and controversial kitplane projects in recreational aviation's long history! To the more cynical, it's easy to look at the Lionheart and say, "Why, in this day and age, would you design a biplane with a round motor and then produce it in composites? Isn't there a more modern approach to this mission?" And then when you sit down and listen to designer Larry French lay out his design parameters, and you realize that, no, there isn't a more modern way to approach this problem. Not for the dollars involved, anyway. Part of the reason modern hardware isn't up to this task is that the number one requirement for carrying a large load at high speeds is horsepower. Lots and lots of horsepower. The original Lionheart mission envisioned carrying no less than six people at no less than 200 mph true airspeed for a minimum of 1,200 to 1,400 miles. No matter how you juggle the numbers, the immutable laws of physics say that it's going to take a lot of ponies to do the job, more than is commercially available in flat motors. For practical flat engines 350 hp is about the upper limit, with the humongous, eight-cylinder Lycoming IO-720 giving 400 hp (list price approximately $100,000). Cost alone caused Larry French to look elsewhere for his power. If you focus on the power-required question while keeping one hand on your wallet and then look across the engines currently available, one answer becomes obvious: It's hard to beat the old R-985 Pratt & Whitney on a dollar per horsepower basis. The 985 kicks out 450 hp, has a supercharger (not a turbocharger) so it still produces plenty of horsepower at high altitudes (300 hp at 10,000 feet), and sells in the $20,000- to $25,000-range in overhauled condition. Parts are nearly as available as Lycoming/Continental parts, and the huge number of the engines in service has given rise to a support industry that has even begun to produce new cylinders. In short, when it comes to brute horsepower, the R-985 offers just about the best dollar-to-horsepower ratio.

For instance, when the design parameters include the ability to carry six full-size passengers, the size and general shape of the fuselage following a Pratt & Whitney is foreordained. It has to be long. It has to be big. The engine diameter allows a cabin that's 50 inches at the pilots' shoulders and widens out to 52 inches at the second row of seats. Griffon apologizes for the paltry 42- inch width at the rear bench seat, which coincidentally is the same width as a Cessna 172 cabin. So what about the Lionheart being a biplane rather than a superlong wing, high-aspect ratio, slick-as- a-pool-cue monoplane? Larry's answer is fairly simple. Keeping the stall down to around 65 mph, as per Federal Aviation Regulation Part 23, meant keeping the wing loading down. This, in turn, requires a given amount of wing area. To do this in a single wing would require a very long wing, which would require substantial structure—and weight. Besides, most home workshops can accommodate short wings, but few can house really long ones. And Larry will freely admit to being infatuated with the looks of the Staggerwing Beechcraft. In his words, "It just looks cool!" Besides, Beeches' goals were similar to his. If they'd had composite technology available to them in those days, the Staggerwing would have looked suspiciously like the Lionheart. Or is it vice versa?

It's obvious the Lionheart is a sophisticated airframe, something that many overlook because of the biplane configuration. With a 5,200-pound empty weight and a 2,086-pound payload, this is far from being a small design project. But Larry French and the Griffon Aerospace boys are up to it because, among other things, they are professional engineers. Lionheart is simply a subdivision of their company, which designs and makes a lot of exotic stuff for the military and industry. They don't depend on the Lionheart for their bread and butter. They do, however, depend on the Lionheart to buoy their spirits and keep their interest alive. Even so, Larry says the Lionheart project is standing on its own two feet. The airplane isn't cheap; the kit runs $99,000, with another $18,000 for the quick-build option. At that level, kit sales can't rival the number of RVs sold. There is an interesting fact about Lionheart sales, however: Introduced only a few years ago, there are already two, and nearly three, customer-built airplanes flying. That is significant and says a lot about the basic design and the customer support. Incidentally, all the kits sold have been quick-builds, and Larry says he's not sure they'd sell a kit without the quick-build option because it includes so many critical operations. Even though the basic kit includes a fully molded fuselage, wing skins, and spars, the quick-build option includes attaching the spars to the bottom wing skins and some serious mating of control surfaces to the fuselage that would be difficult for the average builder. I'll admit to being one of those who had watched the Lionheart from alar but didn't really consider it a serious contender until Sun 'n Fun, when Griffon displayed a customer airplane next to the factory prototype. That impressed me because I figured the prototype was an orphan. I didn't realize customers were getting their airplanes finished so quickly. It wasn't until I approached the airplane to fly it that I began to take note of some of its design characteristics. When walking around the Lionheart, it's hard to get used to a bi- plane that has no seams. Other than one cowling joint and the doors, you can run a fingernail from the spinner to the tail and never have it hang up on anything. Ditto the wings. Very clean. The airplane has flaps on all four wings, as well as four ailerons.

It's hard not to be impressed by climbing up an air-stair-type door into a narrow aisle that starts between the second and third row of seats. This isn't a cockpit. It's a true cabin. And the aisle is at least hipwide so you don't have to squirm between seats on your way to the flight deck. What you do have to do, however, is remember the main spar box is hanging out of the ceiling just behind the pilots' seats. It looks like a real head knocker. Once you drop into one of the front pilot seats and move it forward, it's hard not to be impressed by the visibility. The side windows wrap down the fuselage much farther than a Staggerwing, and the effect on visibility is noticeable. You sit far and high enough from the center of the engine that you can very nearly see past the engine by moving your head outboard. When taxiing I found it took only the tiniest turn to completely uncover the centerline ahead of the airplane. Looking out the other side is a waste of time because the instrument panel covers the world over there. Even so, the ergonomics are such that, even on the blind side of the airplane, visibility is much better than in something like a Cessna 195 or Staggerwing. The instrument panel is, obviously, huge, but it was kept a little smaller than was possible, which helps with the visibility. Filling up the entire panel would be difficult. There's room for every electronic gadget ever built. While I was fussing with my seating position, Griffon's demo pilot, Gordy, fired up the Pratt & Whitney. Just listening to the characteristic whine/grind/cough sequence is enough reason to want to build the airplane. Incidentally, the reason the airplane has control sticks rather than yokes is because, as Larry French, puts it, "They just make us feel better." I agree. Gordy gave me the airplane the minute things were whirling, and I began picking my way to the taxiway. I was halfway down the mile-long taxiway when I realized that about half the world was watching us. As I said, no pressure. I experimented with the tailwheel and did S-turns of varying degrees and found that the designers had really done their homework because the airplane responds very proportionally, with no heavy airplane inertia attached to it. It felt very natural. Then there was the takeoff, which was a wall of muffle noise rolling over us and the runway flashing past us. As the tail come up, the runway suddenly filled the entire windshield, rather than hunkering down out of sight behind the nose. I kept the tail down slightly and let it decide when it was ready to lift off. It found a speed it was happy with and separated cleanly. As I flickd the gear switch up, I was squinting into the haze trying to pick out the two or three airplanes that had taken off in front of us. I would have loved to have brought the nose up to 100 mph and let her rip, but as it was we were well above traffic while still turning out of the pattern. Best rate of climb is listed as 1,700 fpm (at 4,200 pounds), and it felt like it. Gear retraction required no trim change, and I forgot about it as soon as I flipped the gear switch. A normal climb setting of 30 inches of manifold pressure (30 MP) and 2000 rpm took us to the cloud base in a heartbeat, and I pushed over, setting up a low cruise setting of 22 MP/1800 rpm, which reduced the engine's rumble to a mumble. Like most composite airframes, there wasn't anything to vibrate and amplify the noise, and the fully insulated cabin killed much of what noise there was. Using the stick's top-hat switch I shot past the desired trim setting because the trim rate is fairly high. All it took was a gentle bump, not a fullblown push. It took about 10 seconds to get used to it. As the speed worked its way up to about 165 knots indicated (175 knots/205 mph true airspeed), we rocketed around in the gloom looking for a bright spot where we might get some altitude. They say 190 KTAS is a normal 1900-rpm cruise at altitude, where the supercharger is really doing its thing. It looked lighter out west, and in a matter of minutes we found the ceiling going up and the sun coming through. A gentle tug on the stick put us at 2,000 feet under a broken ceiling. Not knowing how local the holes were, we opted to stay beneath it and do what we could to evaluate the airplane. First on the list was the rudder, which had been giving me little fits since takeoff. It was light and powerful, with little or no selfcentering tendency, so it was easy to overdo it. I spent some time doing rudder doublets and other stability stuff trying to decide whether it had enough fin or not and concluded it does. It was plenty stable in yaw, but the rudder was just as easy to over-control. Larry said they are working on increasing the self-center tendency. While rolling hard right and left I noticed another curiosity. At cruise speed the airplane rolls asymmetrically. When I rolled hard left, it took very little rudder going in but a fair amount coming out. When rolling hard right, it takes more rudder going in but only a little coming out. You could fly the airplane a thousand hours and never see this characteristic unless you asked it for a much higher than normal roll rate. The roll rate was pretty brisk, in the 70- to 80-degreeper- second range, and very Beechcraft-like in its smoothness, although the aileron breakout forces around neutral were a little higher. It had a little more adverse yaw than a modern Cessna or Beech, but not excessively so. The airplane probably needs rudder trim because the airplane asks for rudder to center the ball if you're above or below cruise speed. The airplane carries a humongous amount of fuel, 152 gallons in four tanks in each wing. The fuel selector has four positions, but they say they are going to go to a "both" position for the top wings to eliminate fuel imbalance problems. When we first took off, the left wing was noticeably heavy and didn't lighten up until we'd burned nearly half an hour of fuel out of it. I wanted to do some deep stall investigations (hold the airplane in the stalled condition and try some aileron inputs), but the ceiling held us to normal stalls, which were real eye-openers. We were somewhere around 4,400 pounds, but the airplane had the stall characteristics of a Cherokee. Maybe even better. When I did stalls in the clean configuration, I kept sucking the stick back waiting for a break, but with the stick against the stop, all I got was a gentle mush and a slight, straight-ahead bobbing of the nose as it searched for more speed. I thought to myself that the dirty stalls would undoubtedly be different, as they are in most airplanes. With full flaps (40 degrees) and the gear down, I repeated the exercise and got exactly the same results. Exactly! The stalls were just as gentle when dirty as when clean. Clean, they happened at around 60 knots and dirty around 55 knots. We did one in a steep bank, and it obediently rolled level and bobbed a little. The Lionheart flew again after I released the stick and added the slightest amount of power. Doing a stall with 1000 rpm and just a touch of power brought the numbers down to below 45 knots as the prop put airflow over the flaps. As we picked our way back toward the airport, I began slowing the airplane down and feeling it out in approach mode. Even though it was really clean, a power reduction combined with a hard turn brought the speed down to where 1 could extend the flaps 10 degrees out, at which point the plane became a model citizen and very easy to control. Approach control told us to land on the taxiway, which is about 50 feet wide, rather than the main runway. That's approaching narrow for most blind airplanes, and all the way down final I kept waiting for Gordy to say, "I've got it for the landing," but he never did. At the time 1 thought he was being pretty gutsy, but later I realized he knew the airplane would protect us both with its manners. I used a conservative 100-knot approach, slowing to around 85 when close in, and I had the runway in sight all the way down. We ran the flaps all the way out and a gentle bump on the top-hat switch put the airplane on speed, and it stayed there. On short final 1 decided to cancel out a fair crosswind from the left with a little slip. In the flair 1 fed in just a touch of power and began flying formation with the ground for a wheel landing. Hold it! Hold it! Work it down in millimeters and let the landing surprise you. The wheels rolled on, and I let it sit there for a second before pinning it on with forward pressure. I kept waiting for it to bird-dog into the wind, but it didn't, or the slight amount of rudder work I was doing was taking care of it. There was almost no rudder movement at all during the entire rollout, and if you consider the airplane type (roundengine taildragger), the visibility was terrific. Even after I let the tail down, visibility was still good, and its runway, er, taxiway manners were excellent. Is the airplane hard to fly? Only if you make it so. It's straightforward in what it expects of pilots, and it is expecting nothing a pilot shouldn't be doing anyway. On landing just keep the tail behind the nose, cancel out the drift, and hold the landing attitude. That's it. I have a feeling, however, that with its high center of gravity, if you decide to let it really get away from you, the results are going to be predictably spectacular. However, with a gear that wide, any such incident would be your own fault. To any who have decided to carry huge loads long distances (1,400 miles plus) and do it with class, the Lionheart is a contender.

|