|

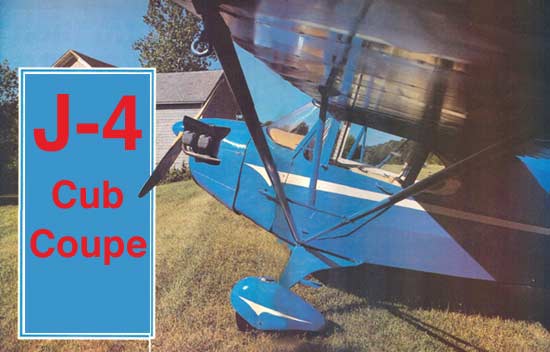

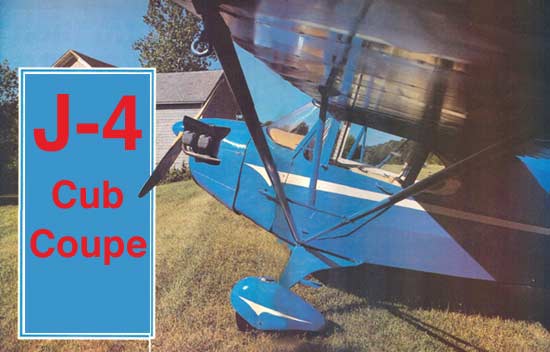

The "Other" Piper

Cub |

PAGE THREE Most of the important changes came about after the first year of production. with the introduction of the 1940 model. The most obvious change in the '40/'41 models is that the exposed engine cylinders of the 1939 J-4A have been cowled in with an extremely pretty piece of sheet metal, possibly one of the prettiest Piper ever built up to the Twin Comanche Tigershark cowls. At this time, 1940, they were doing their very best to give the coupe a fancier look to entice more people into using it for business (we think). The cowl had a little chrome trim on it and the instrument panel was completely overhauled and regrouped. All of the controls were moved into the center of the panel, this included putting the carb heat and fuel cut right in the middle, along with the mags and throttle. It was an unusual arrangement for an airplane but one that is quite attractive. All of the J-4s had the same structure, which is to say they were built like a J-3 Cub. The fuselage is steel tubing with wooden fairing strips covered with fabric. The wings have wooden spars but the ribs are riveted "T" shaped aluminum with wooden tip bows, as were all rag wing Pipers. Only the spars in postwar airplanes were changed to aluminum. As with most airplanes of this age and construction, rust and rot are by far the biggest enemies of the airplane. Since they sit tail down, any water that works its way into the fuselage tends to drain to the back and, if there aren't sufficient drain holes, the water tends to pool in the back at the bottom of the rudder post. That's where the rust first begins. You don't hear much talk about it anymore, but it used to be a well-known fact that before you bought an airplane, you got back in around the tail and poked it a few times with an icepick and hammer to see if you had good metal. These days you might have a little trouble getting somebody to let you poke their airplane so you'd better look at its metal as closely as humanly possible. As far as the wings go, it's highly unusual to have a truly rotten spar unless the airplane has been left out in the open for many, many years and the fabric drain holes are plugged. But, it does occur and the spars should be looked at closely. Also, since the fittings at either end of the wing struts are steel, they should be inspected for rust and/or pitting. On a J-4, something that heads the list in the investigation is the cowling itself. The J-4A with exposed cylinders has a nosepiece and a top panel that are compound curved and were most likely formed in a die. The !ate models have even more complex metal work up front. While there are lots of companies making new sheet metal for J-3s, you might be hard pressed to find a good replacement cowl for a J-4. There are only one or two places that are capable of hand forming new metal like this. One we are personally aware of is Raceway Equipment in Riverhead, New York (tell Joe we told you to call). (Unfortunately, old Joe passed away sometime back, but quite a number of new, young craftsmen have popped up who know how to run an English Wheel.) As with all Piper aircraft of the period, the wing strut forks at the bottom end have several ADs against them. By this time, if the airplane is flying, those forks have probably been examined and replaced. Since the forks (and new struts) are readily available, it doesn't make any sense not to replace them. The original J-4s used a Continental A-65 with the upward type of exhaust. By now, however, most of them. as with Bob Hunt's J-4A, have been re-engined with surplus L-4 A-65s, or something similar. In these the exhaust is more standard and exits out the back of the cowl. Note. the cast aluminum rocker arm covers on Bob Hunt's J-4 . . . a dead giveaway that it's an ex-military engine. Most. if not all of the ‘40/41 models came out with the 75 hp Continental that gave the airplane a much needed kick in the rear. Going up to a C-85 via a field approval would make a totally different airplane out of it. With the exception of the compound curved sheetmetal the J-4 represents absolutely nothing that is difficult to repair or hard to replace. Although it's not a J-3 Cub, an awful lot of J-3 parts can be used to keep it flying. Otherwise, it's just normal grassroots hardware. If you find a project in a barn somewhere, and you don’t want it, give us a call. We do.

|