If you look out across the ashes of the traditional aviation industry and squint your eyes a little, you might just catch the first movements of rebirth. Somewhere out there in the murk which has remained lifeless for the past decade there are the ripples of new life. New birds are being hatched and are about to take flight.

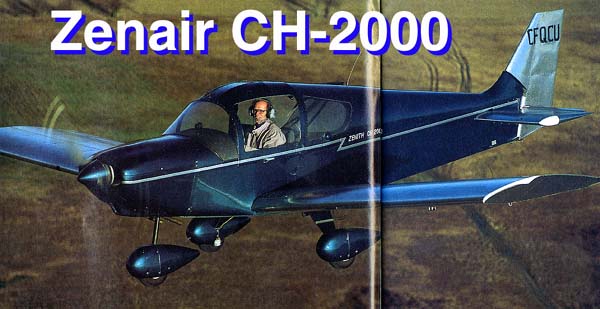

The seeds EAA Headquarters has been sowing in previously barren regulatory ground are starting to sprout as lots of new aircraft prepare to take-on as part of newly simplified certification processes. The one most likely to be first through the process is Chris Heintz' Zenair CH-2000. The CH-2000 stands to be the first "normal" airplane to be certified under the rules of the Very Light Aircraft provisions of the Small Aircraft Certification Program which the EAA and SAMA worked so dligently with the FAA to hammer out.

The new certification categories and aircraft like the CH-2000 are coming along just in the nick of time! At the rate we were going, in another few years we would have had a ring side seat to our own industry's funeral.

We all know the statistics: the average age of the single engine fleet is 35 years and the average trainer is often older than its occupants. We've been beaten to death with the awful facts and the long, drawn out death of main-stream aviation: Nearly 18,000 were produced in 1978 while last year production dropped below 1,000 for the first time in history.

Actually, aviation,

as represented by traditional, certified, built-in-the-heartlands,

aviation didn't die slowly. The majority of it suffered a massive

coronary and fell flat on its face during a horrific period lasting

something less than 3 years which ended in 1985. It only lasted

that long because of its inertia. It was dead before that but

didn't know it.

Actually, aviation,

as represented by traditional, certified, built-in-the-heartlands,

aviation didn't die slowly. The majority of it suffered a massive

coronary and fell flat on its face during a horrific period lasting

something less than 3 years which ended in 1985. It only lasted

that long because of its inertia. It was dead before that but

didn't know it.

To many it looked as if aviation took a long time to grind to a halt, only because it took so long for the controlling regulatory agencies to convence themselves that it wasn't going to magically spring back to life.

Even before aircraft production halted, the EAA was in there hammering away at what it thought was some of the root cause of the imminent demise of light aviation. First and foremost was the basic cost of the airplanes and one of the biggest factors in that area was the mind-numbing cost of certification. The EAA felt there had to be a simpler and less expensive way.

Simple is not one of the words historically applied to the aircraft certification process. The certification process didn't start out complicated, it just sort of "growed" until it was like the famous old Winchester Mansion. It had been added to so often it had dozens of mindless additions, blind stairs and doors leading to no where, all as the result of an aging mind that was bent on dealing with one detail at a time, never looking up to see the big picture or how misshapen and unusuable the structure had become.

Something like 95% of all light aircraft now flying were certified under the relatively understandable guidance of the postwar CAR 3 requirements. Over the years this was progressively modified, primarily because of the increasing sophisitication and performance of new corporate aircraft designs, until it was finally re-designated FAR 23 in 1965. What had been a relatively simple document had slowly been transformed into a huge obstacle to certification because those overseeing its application followed it to the letter. This meant a two-place trainer had to toe the same line as a 20 passenger, Mach .85 corporate blow torch. The result is that very, very few light airplanes were certified under FAR 23.

Incidentally, the cost of complying with certification under FAR 23 is estimated to be about $10,000,000. We put all those zeros because the word "million" has lost some of its meaning.

Aviation's graveyard spiral was just about ready to auger us into the ground, when somewhere in an agency office upstairs a light came on which threw some illumination on both the severity of the problem and some proposals which various organizations had put together to deal with the matter.

When it comes to situations as complex as governmental regulations, solutions don't just happen. They are usually the result of a huge amount of work and the process of simplifying is often as complex as the regulation they are trying to debug.

In the case of certification, the solution got its start when the EAA, with the AOPA's concurrence, forwarded their vision of what light airplane certification should look like. But, that was the early 1980s and the situation hadn't gotten bad enough yet that the FAA was ready to listen. Fortutately, in the past several years, the FAA's attitude has turned around to one in which they are looking for ways to say "yes", rather than having applicants prove they are worthy by jumping over an endless series of hurtles.

The delays may have worked to every one's favor, since both sides learned a lot in the interim and both changed their stances slightly. Even the Primary Airplane Category concept, as originally proposed by the EAA/AOPA, didn't meet the need exactly.

Then Paul Poberezny, acting as an individual, rather than the EAA's founder, submitted his own plan, the Small Aircraft Certification Compliance program. This program took all the non-essential stuff out of FAR 23, reducing it back to CAR 3 simplicity and added a few limitations of its own, primarily in limiting the process to 2 place, fixed gear airplanes weighing less than 3,000 pounds.

The EAA continued to push for some sort of FAA recognition of both the problem and the solution, as represented by some of the programs which it had initiated. As the FAA's attitude changed, the entire regulatory environment began to shift until in 1993, with the EAA acting as a coordinator, meetings were held at EAA headquarters where the FAA, SAMA and the EAA's team leaders worked to hammer out the final chapters of a new series of certification programs.

One of the most important

things to come out of these meetings was yet another certification

category, the Very Light Airplane (VLA) category. It was a further

version of the Small Airplane Compliance program,in that it too

simplified FAR 23 but carried the limitations one step further

to reduce the allowable gross weight to 1,645 pounds and the stall

speed to 45 knots (51.8 mph). This category was ready-made for

the development of a new breed of trainer to replace a training

fleet that is growing older by the minute.

One of the most important

things to come out of these meetings was yet another certification

category, the Very Light Airplane (VLA) category. It was a further

version of the Small Airplane Compliance program,in that it too

simplified FAR 23 but carried the limitations one step further

to reduce the allowable gross weight to 1,645 pounds and the stall

speed to 45 knots (51.8 mph). This category was ready-made for

the development of a new breed of trainer to replace a training

fleet that is growing older by the minute.

The day after Canada approved their version of the VLA, Chris Heintz, President of Zenair Aircraft, put in his formal application for the certification of his CH-2000 and, as of this writing, is most of the way through the program.

Knowing he was likely to be the first to certify a new trainer, I hopped on a smoker headed north to have a quick look at what Zenair had going north of the border. Like so many others in sport aviation, I knew Chris and his airplanes only from exposure at fly-ins. From that vantage point he appeared a successful kit plane manufacture who had been around for a long, long time (20 years to be exact), but past that I knew few details. However, since he was making noises about becoming a producer of training airplanes, it seemed logical to drop in and see first hand what he had in mind.

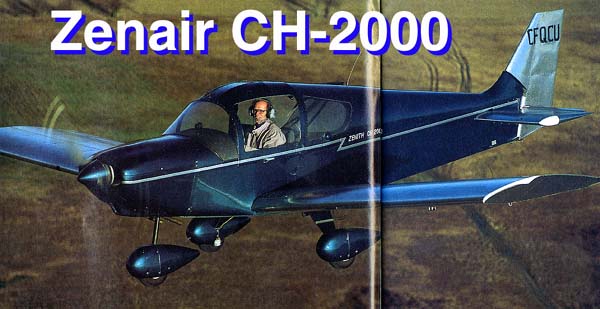

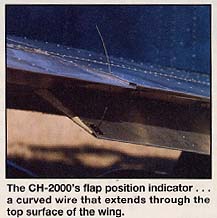

At this stage of the game, it's probably okay to admit that I had a pre-concieved notion of Heintz and his airplanes. Having nothing to judge by, I figured he was working out of a double garage behind his house and probably wasn't interested in hearing other's views on his airplanes. I was wrong on both counts. Very wrong.

In the first place, the Zenair plant on Midland, Ontario's municipal airport (about an hour's ride north of Toronto) is anything but a double garage. His main factory building would do justice to any builder of certified Spam cans and has an interesting soft personality about it, a touch I hadn't expected in either the building or in Chris. He has taken some pains to put character into the building in the form of rustic wood work both inside out out. It's impossible to totally disguise a steel building that size, but he's done a lot to make it homier, a move not many would have made. This very much reflects the Chris Hientz Approach to business, which in a word is "...keep it small, keep it friendly..."

Although his accent is very distinctly German, Chris is actually a French national, but he was brought up on the border of the two countries and went to school at VLH in Switzerland, their equivalent of MIT. After graduating he went to work with AeroSpatiale doing aeroelasticity work on the Concorde, but tired quickly of being a small number in a huge company.

Going to work for Avions Robin he quickly became their chief engineer. He was also their only engineer, since they only had 20 employees at the time. It doesn't take much imagination to see the similarity between the Robin series of tourers and aerobatic airplanes and the Zenair machines. Since Chris was the father of both, the similarity isn't accidental.

Chris speaks highly of Robin and what he learned there.

"When you are doing most of the work yourself, you learn to be very careful," he remembers. "Since so much is riding on what you do, you don't take any chances."

But Chris isn't fond of large companies.

"When Robin only had 20 employees, " he says, "it was much more fun and everyone could see what they were contributing. When it reached 200 employees, I knew it was time to look elsewhere."

"Elsewhere" included a stint in Brazil where he worked for Embraer, but "...it was just too hot.." Some might say he over compensated since his next stop was Toronto and deHavilland Aircraft.

But, once again, the size of the company got to him and, with the help of a friend, he moved to Midland and began to get serious about building little airplanes.

The Zenair series of airplanes are readily idenifieable since, with the exception of their sole high wing STOL aircraft, their configuration and general outlines have obviously evolved from one into the other.

Chris explains this easily. "When an engineer has a good design, he doesn't go back and start over, each time. He just refines it, by making subtle changes here and there. That way he knows he is starting with a known and proven design which minimizes the unknowns in the new design."

This is the exact philosophy Hientz used in designing the soon-to-be-certified CH-2000. Starting with one of his more popular homebuilt designs, the CH-200, he looked at it both from a producibility point of view and its suitability as a trainer, as defined by the VLA certification process.

After studying the training market, he decided the mechanical aspects of the airplane were almost as important as how well it flew. For a flight school to make money the airplane has to be easily maintainable, easy to repair and must be produced at a cost which keeps the flight school's investment to a minimum. In other words, the airplane has to be as simple as mechanically possible while still providing the flight characteristics which are recognized as being suitable for the flight training role.

In walking around the CH-2000 before we strapped it on, there was no doubt Heintz has kept the airplane simple. In fact, it could almost be called rudimentary, which, considering the airplane's purpose, is a compliment, not a criticism.

The first thing anyone will notice is that the wing looks to be nearly a foot thick.

"Yes," says Heintz "I guess fat wings are one of my trade marks. The depth lets me build a strong wing that is very light and gives excellent stall characteristics as well. Under 200 mph, the thickness doesn't contribute significant drag, so why not use it for its other advantages?"

At 16% the spar depth available is almost amazing and inspecting the wings during assembly, it was noticed that the spar caps are aluminum bars, rather than extrusions, which keeps the cost down.

The spars are one of the few parts of the airplane which use driven rivets, rather than Avdel blind rivets. Chris is a real proponent of using these rivets which are applied from one side of the structure and require no bucking.

He says, "The blind rivets eliminate most of the skill required in aluminum fabrication and make it easy to put together a structure quickly with fewer people."

The horizontal tail is a stabilator which Chris says he chose because it enabled him to easily control the elevator stick forces by properly sizing the servo tab.

The all-flying verticle

tail is another Heintz trademark which he says gives the airplane

tremendous crosswind capabilities, another factor important to

flight school operators.

The all-flying verticle

tail is another Heintz trademark which he says gives the airplane

tremendous crosswind capabilities, another factor important to

flight school operators.

On the airplane we were flying, the wings were bare aluminum and the stabilator had large areas of fresh aluminum showing where modifications had been made. The original wing wouldn't meet the VLA stall requirements so Chris built a new wing and modified the tail. In so doing, he eliminated the fowler flaps and went for split trailing edge flaps.

"When we found we stalled two knots too fast, " he says, "we had the option of going to even more exotic Fowler flaps, which would be much more complicated to build and maintain, or go for a slightly larger wing. We went for the new wing since it would keep the cost down. The split flaps are also simple and don't provide nearly as much lift as they do drag. Since we now stall at something just over 40 knots, we don't need lift from the flaps."

The wings have Hoerner tips incorporated into the structure, rather than being added as separate pieces. This design moves the tip vortex out and, according to Heintz, gives an effective span at least a foot longer than what would be measured with a tape measure.

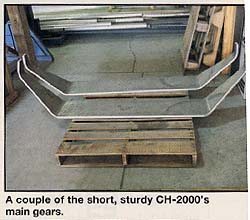

The landing gear on any trainer takes a tremendous beating and this is one area to which particular attention has been paid, both in enabling it to survive the training environment and making it easy for the operator to maintain. The strength of the design is obvious because the main gear has to be one of the biggest pieces of aluminum every put on a light airplane of any kind. It approaches a foot in width in the middle and is nearly 3/4 of an inch thick.

Besides being as robust as an anvil, the gear is attached to the outside of the fuselage box rather than being two pieces inserted into complicated gear boxes in the structure. The fuselage just sits on top of it with two gear clamps holding it in place! Although this first looks crude, it is actually inspired simplicity. A flight school operator doesn't care how fast his trainers are, just how well they hold up and how many hours of maintainance per flight hour are needed to keep them flying. One glance at the main gear leaves little doubt that this is one gear that is going to need very little maintenance.

The nose gear is made of 4130 tubing and uses bungees rather than springs or oleos for shock absorbsion. This is another move towards simplicity and maintainability. Also, since it is attached to the firewall rather than the motor mount, there could be some concern that a hard wheelbarrow landing could damage the firewall. This is unlikely since it appears as if the lower gear leg is designed to fail before the firewall does.

Every mechanical part of the airplane that is hidden inside a structure is accessable through much larger than normal inspection panels. There is even a special panel in the bottom of the fuselage that, when six screws are removed, lets a man crawl into the aft fuselage for inspection or repair.

When we saddled up, the first thing noticed is that the wing walks go clear to the trailing edge of the wing and are made of beefy .040" with two extra ribs inside of them. This is the result of empirical testing: The crowds at Oshkosh quickly showed Chris how easily an endless procession of feet can beat up wingwalks and flap edges.

Having doors on both sides makes getting into the airplane really easy, although a hand hold on the bottom of the windshield frame would make it easier to let yourself down into the seat. Also, because the cabin top is so much higher than most airplanes, once I was seated, I couldn't reach up to get the overcenter mechanism of the door released to close it. All minor details.

Once inside the cockpit, the overall size really grabs you. Most of us instructors are used to being crammed into fairly small cabins, but, before laying out the CH-2000 Heintz took a yardstick to all the other trainers and added a few inches. His cabin is 46 inches as compared to a C-152 at 38 inches, a C-172 at 41 Inches and a Cherokee at 42 inches. This extra width and hieght is very, very noticible. And welcomed.

In looking around the airplane it is noticed that a lot of parts which would normally be formed or cast in other airplanes are weldments in the CH-2000. The door frame, for instance, is welded tubing, as are the control yokes and other parts. This is part of the "Chris Heintz approach to building airplanes at a profit", more of which we'll cover later. He wants to keep vendored parts at a minimum and won't go for the tooling cost to produce castings or formed parts until the quantity can justify the cost. The weldments he can make in-house and, when the quantity justifies it, he'll switch over to other methods.

Even the control system tries to eliminate vendored items in favor of in-house manufacture. There are only two pulleys in the entire airplane because he uses push-pull tubes whereever possible, including in the aileron system. This eliminates chains and cogs and all the other parts normally associated with a yoke system. His systems use a little more labor, but he considers that a fair trade-off.

The Lycoming 0-235

fired up and sounded just like it does in any other airplane and

I immediately found another feature I don't like in a trainer...a

vernier throttle. Apparently he's heard this from a bunch of other

instructors, since he was going to change this on production airplanes.

He's had a lot of instructors fly the airplane, so anything I

commented on was simply another voice added to a long list he

was keeping on every aspect of the airplane and few liked the

vernier throttle.

The Lycoming 0-235

fired up and sounded just like it does in any other airplane and

I immediately found another feature I don't like in a trainer...a

vernier throttle. Apparently he's heard this from a bunch of other

instructors, since he was going to change this on production airplanes.

He's had a lot of instructors fly the airplane, so anything I

commented on was simply another voice added to a long list he

was keeping on every aspect of the airplane and few liked the

vernier throttle.

The nosewheel steering was just about perfect and even though it was absolutely direct, was ratioed in such a way it felt natural and required nothing unusual in the way of pressure. The same was true of the brakes. Just right.

Because you're sitting so high in the airplane visibility is excellent, something which Chris personally feels very strongly about. In all areas of operation, the visibility couldn't have been better.

The elevator trim is a rocker switch mounted vertically in the panel above and to the right of the throttle and apparently I was just another voice in the choir, when I said I thought it was mounted upside down. Nose down trim required pushing the top of the switch and nose up trim meant mashing the bottom portion. This definitely seemed backwards. The mounting position, however, was dictated by the Canadian Ministry of Transport which says the switch should be oriented in the way that represents movement of the airplane about its center. That may make sense to them, but to a student, up is up and down is down. I'll bet the FAA lets Chris change that.

As I squeazed the vernier button and gently fed the power in, my plan was to lighten the nosewheel and let it run on its mains until lift off. Chris said the right approach was to pull the nose off and then let go immediately. I don't think I understood him at the time, but a few seconds later I did. When I tried picking the nosewheel up, It took an inordinate amount of pressure. So much pressure, that when the nose finally came up, I had to immediately neutralize eveything to keep from overrotating.

I mentioned to Chris that I personally thought that wasn't going to be a workable situation and would make it difficult for students and instructors. As I went through the flight and then shot a bunch of touch and goes, I felt that problem out and found that even with lots of aft trim the rotational forces were still way too high and out of character with the rest of the airplane's handling characteristics. Chris added another item to his list.

With two FAA-average people onboard and half tanks we were showing about 850 fpm on the VSI at about 70 mph (best rate) with an OAT of about 25 degrees F. At that speed we were climbing at a ridicuous angle. 75-80 mph brought the nose down for much better visibility and only cost about 100 fpm.

A noticeable amount of rudder was needed to keep the ball centered during climb. It was similar to a Cherokee 140, which is good, since it teachs the student his feet are needed at all times.

As we leveled off, the nose went way, way down and the visibility just kept getting better. It was during this process that I found the trim rate in cruise to be just a tad too fast, making it a little difficult to get perfect trim. Another easy fix.

I messed around with the usual pitch stability and phugoid stuff and found the airplane to be positive in pitch in all areas, but not strongly so. It will always head back in the right direction, but isn't in a hurry to level out. This is not a negative, since it is only a little looser in that area than most trainers and there's a strong possibility that, when he builds a new stabilator to replace the modified one the pitch stability will tighten up some.

In normal flight, the controls are, well...very normal. They are probably closest to a C-172 in break-out forces, accelerations, etc. They are exactly what would be expected in a trainer.

In separating the controls and using the ailerons by themselves I found the airplane had fairly pronounced adverse yaw, which I was glad to see. It is nothing like an old Champ, but it is nice to see a trainer that requires the student to use his feet to keep the ball centered. The C-152 has a little adverse yaw but not enough to really be noticeable and an instructor has to work hard to keep his students coordinated. Increasingly, instructors don't do that. A Cherokee has practically no adverse yaw and students are hard pressed to see the results of good coordination.

The CH-2000 has just the right amount of yaw and should produce students who are coordinated, since they'll actually be able to see why they need to use their feet. This is one of the biggest problems in flight training today and is the reason so few pilots actually coordinate the controls. If airplane's had controls like the CH-2000, the problem wouldn't be nearly as severe.

The rudder ratio is a little quicker than most airplanes and, because the rudder has lots of authority, this produces a lot of effect with out much movement. At some point, when he's doing refinments, it would be interesting to see how instructors would react to his slowing the rudder ratio down just a bit.

The stalls are pretty much what would be expected with a wing that fat. We staggered along with the yoke nailed to the stopt and the airspeed hovering around 45 - 50 mph. There wasn't much buffet.

While we were stalled, I tried the ailerons with no rudder and found the down aileron would further stall the down wing and induce some yaw, giving the opposite effect expected because the airplane would roll into the down wing. This isn't unusual, but it does require that the student absolutely coordinate in making corrections while stalled. Since the airplane hadn't been through a complete spin series, we couldn't investigate cross controlled stalls.

Accelerated stalls in a 30 degree bank produced only a mush with almost no roll to the outside.

I played with the flaps in doing stalls and found about all they did to the stalls themselves was make the buffet much more obvious. However, I quickly found the flaps could steal speed in a heart beat, if you weren't watching things carefully.

As it was flying in pre-production form, the airplane had a full 60 degrees of flap available. With split flaps, it's a rule of thumb that any thing past about 15 degrees gives much more drag than lift. In this case, I found if I held the nose attitude at that needed for a normal 75 mph glide, while the flaps were in the process of extending, something like 12-15 mph disappeared immediately. Later we played with varying amounts of flap extention on approach and decided about 28 degrees was really all that was needed and any more was likely to cause more problems than it was worth.

To a pilot, those 60 degrees of flaps are as good as having a speed brake, since you can make really steep approaches with them. But in that type of an approach, it doesn't take very much of a nose attitude change to lose a dangerous amount of airspeed and a student may not be that observant, especially in turbulence. Chris agreed with this.

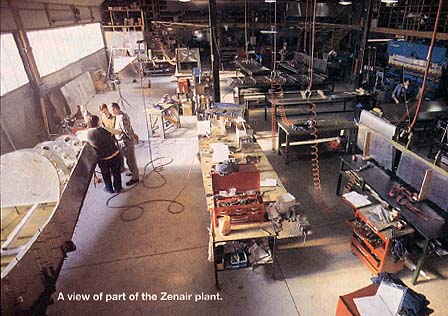

A word about the C. Heintz Super-simple Flap Indicator: It's super simple! Its a wire coming up through the trailing edge of the wing and, as the flaps go down, the wire disappears. A neat idea, but most who have flown the airplane would prefer a flap indicator on the panel. Also, while turning your head to monitor the flaps, the nose has to be forced down to maintain speed, which isn't an easy thing for a student to do.

Although it isn't a number worth noting on a trainer, since it isn't important to the mission, the CH-2000 cruises about 115-120 mph indicated.

Back at the airport I flew a 1,000 pattern and what appeared to be a reasonable downwind distance. I killed the power on downwind at the end of the runway, setting up for a power-off landing. I ran out about 1/3 flaps on base leg and made the runway easily, but still had to keep looking at the trim switch to keep from screwing up. As it was, I found it wasn't an airplane that trimmed to speed immediately. For that reason, I was having to pay more attention than normal to the nose attitude to hold speed. This, again, is an easy fix but one that will be necessary to make it a little easier for students. We want them to work to hold speed, but this may be just a bit too much.

Using 70 mph on final, there is enough float left during flair to give a student plenty of time to get the airplane set up. Hopefully, however, they'll do a better job of setting it up straight than I did. For some reason, I was always a few degrees off heading, which was a pilot problem, not an airplane problem.

At no time during any takeoff or landing did my feet come into play for directional control. The airplane acted like it knew exactly where it was supposed to go.

If no flaps are used, holding the nose off is not a problem, but as more flaps are run out, it becomes impossible to keep it from flopping on. I made a couple of full flap landings and besides coming down like an elevator, the flair and landing were the same as with half flap. The round-out wasn't critical at all, which surprised me as I expected the speed bleed-off to be critical with those barn doors hanging out so far.

It's not really fair to criticise a pre-production airplane, the way I've been doing, since every negative comment I made were items already on his hit-list. Still...

Heintz will be producing his CH-2000 both in Canada and in his new plant in Mexico, Missouri. When ask why two production facilities he said, "That way they stay small. I don't want them too big. We can do almost an airplane a day, which is 200 a year, if sales warrant and if we need more, we'll start another plant some place else. "

What he didn't say is that the small-plant concept also limits liability, if each is set up and owned separately.

Presently, he is showing a staggering amount of logic and rational thinking. Rather than projecting the usual 400-1000 airplanes a year we're used to hearing from fledgling airplane manufactures, Hientz is starting out at one every two weeks and will increase, as needed. With his current tooling and work force, he can easily meet any expected demand and not over extend himself and that's the key to survival.

As Chris puts it, "Look at the advertisers in magazines 20 years ago and you'll find Zenair. Look at them today and we're still there, but where are the others? We're not here expecting to get rich. We just want to still be here in another 20 years."

More power to you Chris, we like your thinking!