Oshkosh '97 was awash with the exciting, the unique and the historic but there was one singular moment which combined all three factors in a thoroughly unusual manner. It was missed by many but remembered by every single soul who witnessed it: That was the exact moment when pilot Ed Erickson ordered his flight engineer to bring the mixtures to idle cut-off on Amjet's Avro MR.2 Shackleton.

As the big 2,450 hp Griffons wound down and the counter rotating props dissolved into individual blades from what had been shining disks, spectators were treated to a truly unique sight. Watching four, six-blade counter-rotating props wind down at the same time is like watching some sort of ritualistic mating dance between huge metallic spiders.

Oshkosh

'97, like all before it, had it's own personality and, for many,

stood above years past in terms of new and unusual airplanes in

all areas. However, if size, engineering fortitude, and a determination

to keep a complex machine flying count for anything, Amjet's Shackleton

had to be near the top of most folk's list.

Oshkosh

'97, like all before it, had it's own personality and, for many,

stood above years past in terms of new and unusual airplanes in

all areas. However, if size, engineering fortitude, and a determination

to keep a complex machine flying count for anything, Amjet's Shackleton

had to be near the top of most folk's list.

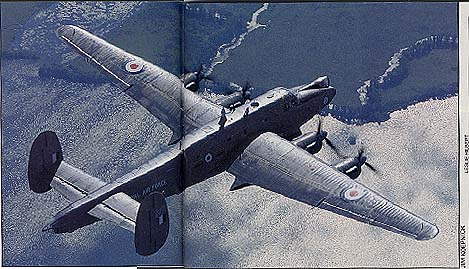

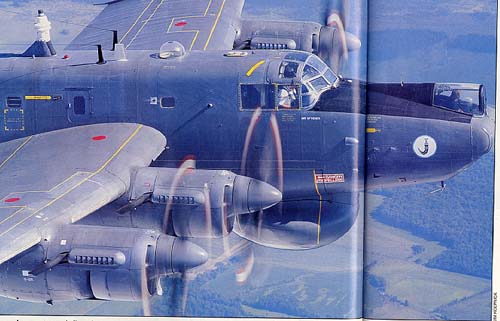

When Erickson brought the airplane in for what appeared to be an effortless landing at Oshkosh, many experts glanced up and mistakenly identified the airplane as a Lancaster. The confusion is understandable as the Shackleton is descended from the Lancaster via Lincoln and it shares many of the family lines. The similarities, however, are more generic than specific because the Shackleton is a breed unto itself.

When WWII was over, the RAF had to begin planning ahead. Besides its wide array of indigenous bombers, including the Lancaster, during the war it had been using a large number of lend lease machines, including B-24's. Although Bomber Command was hard at work hammering away at an enemy on the mainland, they couldn't forget that, as an island nation, they had to continually protect their shores and the sea lanes that were its lifeline. For that reason, patrol bombers were constantly aloft, droning through the cold Atlantic sky seeking out submarines and fleets that posed threats to shipping. Many of those aircraft were B-24's.

At war's end, under the terms of lend lease, the RAF had to either return, or destroy those thousands upon thousands of aircraft which had been lent to them. Since the US had enough problems just figuring out what to do with their own surplus airplanes, they didn't want the majority of lend lease airplanes back, so most were destroyed. This meant Britain had to begin planning for a new series of home-grown long range bombers for the coming decades. The Shackleton was the result of that planning.

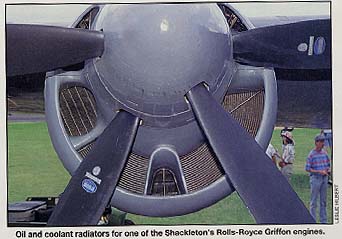

Avro responded

to the governments request for design proposals with their Model

696, eventually to be named Shackleton after the explorer, Sir

Ernest Shackleton. The Shackleton borrowed on the Lancaster and

Lincoln bombers in that it used a modified version of their wing,

but a completely new, larger fuselage. Also, the airplane was

fitted with 2,450 hp Merlin Griffon engines driving six-blade

counter rotating props. The airplane went through three major

marine reconnaissance (MR) versions including the last, the MR.3

which utilized a nose wheel. Amjet's airplane is a MR.2, which

was the most utilized and longest lived version.

Avro responded

to the governments request for design proposals with their Model

696, eventually to be named Shackleton after the explorer, Sir

Ernest Shackleton. The Shackleton borrowed on the Lancaster and

Lincoln bombers in that it used a modified version of their wing,

but a completely new, larger fuselage. Also, the airplane was

fitted with 2,450 hp Merlin Griffon engines driving six-blade

counter rotating props. The airplane went through three major

marine reconnaissance (MR) versions including the last, the MR.3

which utilized a nose wheel. Amjet's airplane is a MR.2, which

was the most utilized and longest lived version.

When the Shackleton's were surplused, several were purchased by Air Atlantique in Britain with the idea of putting the aircraft before the airshow crowd as huge pieces of flying history. The British CAA, however, apparently wasn't as enamored with flying history as the aircraft owners and took a very dim view of licensing the aircraft on Britain. One of the aircraft was subsequently flown to the US where it was licensed. Eventually a joint venture arrangement was worked out with the Amjet Aircraft Corp. of the Polar Museum in Blaine, Minnesota which will maintain and operate the airplane along with their other unique aircraft which includes a Fairey Gannet.

Most of

the thousands of Oshkosh spectators milling around within the

shadow of the huge Shackleton undoubtedly thought what they were

seeing was a restored British bomber. Actually, what they were

seeing was a British bomber that didn't need "restoring",

as we usually think of the term, because it was only recently

retired. Amazingly enough, Amjet's Shackleton had been on line

flying maritime patrols as late as 1991!

Most of

the thousands of Oshkosh spectators milling around within the

shadow of the huge Shackleton undoubtedly thought what they were

seeing was a restored British bomber. Actually, what they were

seeing was a British bomber that didn't need "restoring",

as we usually think of the term, because it was only recently

retired. Amazingly enough, Amjet's Shackleton had been on line

flying maritime patrols as late as 1991!

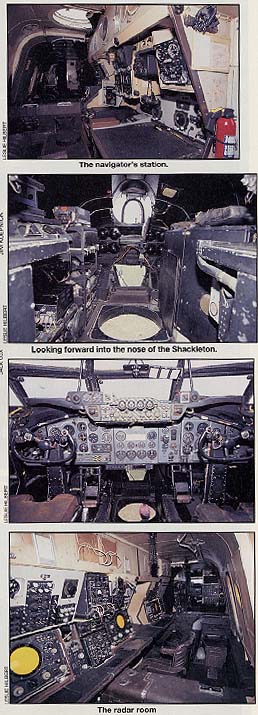

As the cold war intensified, a number of Shackletons, including Amjet's, were returned to the factory to be outfitted as Airborne Early Warning (AEW) airplanes. They were to be radar pickets ranging far around England's shores keeping track of who and what was headed towards the homeland. This is why the cavernous fuselage of the Amjet airplane looks like an airborne command center: Until a few years ago, that's exactly what it was. Once an intruder had been located, the radar operators directed the fighter intercepts. According to Chief Pilot Erickson, the radar units are still operable, although the dish has been removed from the radome under the nose.

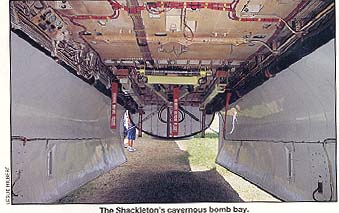

When still operational, the huge bomb bay of the Shackleton carried a wide variety of mines, sonar buoys and any of the wide variety of cold war tools of the trade. It had dual 20 mm guns in the nose with a gunner housed in the less than streamlined canopy, but it really wasn't expected they would have to use them. That's what the fighters were for.

For anyone interested in unique aeronautical details, the Shackleton was a literal treasure throve. For instance, may were puzzled by the narrow strips of bare wood which were inlayed more or less flush and screwed to the leading edges of the wings and tail surfaces. They looked as if a de-icing boot had rotted and fallen away. If that's what a spectator guessed, they were half right. The wood strips were part of the deicing system, but they had never been covered with a flexible boot. That's the way they were supposed to look. Alcohol was forced against the back of the wood stripes and it weeped through to de-ice the leading edges. Considering that the airplanes were designed to fly in one of the most severe icing environments on Earth, the north Atlantic, the systems must have really worked.

The airplane

was festooned with bumps and domes, most of which had something

to do with the radar systems. "...has something to do with

the radar.." was also the answer received when a question

was asked about the huge object on top the fuselage that looks

for all the world like an old fashioned porcelain insulator. Like

we said, unique features everywhere you looked.

The airplane

was festooned with bumps and domes, most of which had something

to do with the radar systems. "...has something to do with

the radar.." was also the answer received when a question

was asked about the huge object on top the fuselage that looks

for all the world like an old fashioned porcelain insulator. Like

we said, unique features everywhere you looked.

Ed Erickson, who has an unlimited letter of authority to fly any single or multi-engine piston aircraft and was checked out by British flight crews, knows unique when he sees it. He says the Shackleton is also a unique flying airplane.

"The airplane's empty weight is nearly 60,000 pounds, the weight of a B-17 at gross. We usually fly it around 72,000 pounds which gives a normal takeoff run of about 3,000 feet. However, the airplane is a true crew airplane and the pilot is totally dependent on the rest of the crew."

Much of this crew-dependence is because the airplane has a number of unusual features that make the rest of the crew necessary.

"A

minimum of five crew members is required to fly the airplane safely,"

Erickson says. "For one thing, once you're out on the runway,

all of the control locks have to be released. That requires a

crewman to crawl on his back into the very back of the fuselage

to pull the elevator lock pins. Then he either has to come forward,

or another crewman, removes the aileron locks which are mid-way

up the fuselage. I then pull a lever that releases the rudder

lock."

"A

minimum of five crew members is required to fly the airplane safely,"

Erickson says. "For one thing, once you're out on the runway,

all of the control locks have to be released. That requires a

crewman to crawl on his back into the very back of the fuselage

to pull the elevator lock pins. Then he either has to come forward,

or another crewman, removes the aileron locks which are mid-way

up the fuselage. I then pull a lever that releases the rudder

lock."

The airplane is full of unique systems which require unusual operation techniques. The hydraulic system, for instance, has no gages to indicate how much pressure is available.

Erickson says, "There are two hydraulic pumps and we check them by opening the bomb bay on one engine and closing it with the number four still running so we know whether the hydraulic pumps are still working."

According to Ed, power management and steering have to be considered one in the same and it is critical in most phases of ground handling.

"The pilot doesn't set his own power, especially on takeoff, because it is critical the power be exactly even from one engine to the next. This is a 75,000 pound tailwheel airplane but it has neither a tailwheel lock nor tailwheel steering. You have to steer it with brakes and throttle. However, the brakes are pneumatic and, from the time you press a pedal, you count one one thousand, two, one thousand, three one-thousand before anything happens. Once the power is up and the airplane is moving, the rudders are effective, but the engines have to be matched to make steering easier. For that reason, the flight engineer sets the throttles."

Besides the control lock removal crew, co-pilot and flight engineer, Erickson likes to have several others as "scanners."

"You can't see what's going on around the airplane, " he explains. "The engines are slung beneath the wings so you can't see if something goes wrong. The airplane has the original fire bottles in the wings for the fuel tanks and engines but I'm not sure how much good they would do."

Considering that the airplane carries 4,000 gallons of fuel, it would be nice to have someone watching to notify the pilot when there's the possibility of fire on-board.

In explaining

the takeoff technique, Erickson further underscores the need for

crew assistance.

In explaining

the takeoff technique, Erickson further underscores the need for

crew assistance.

"After doing all the preliminary checks, checking the mags and propellers, you carefully line up with the runway. Since you can't lock the tailwheel and it's impossible to push the throttles up evenly, you have to set the parking and the flight engineer pushes the throttles up to 30" and checks everything. Then takeoff power is pre-set at 67" of manifold pressure before releasing the brakes."

Erickson says they've done training takeoffs at 80" with the ADI activated and he continually stresses the need for even power settings to ease steering difficulties.

"It is very important the power be even when the brakes are released. You would think it would lurch forward but it doesn't do that. You release the brake and it slowly lumbers ahead and gets rolling. It accelerates about like a Cessna 150 even with 10,000 horsepower. At about 50 knots you pick the tail up and you can see a little better. You have good rudder control, once moving, because there's a lot of air being blown back by those engines over those huge rudders. There is no torque effect because of the counter rotating props, so steering is fairly easy. At 100 knots, you rotate and it flies off quite nicely. Run it up to 125 knots, pull the flaps up and accelerate to a climb speed of 140 knots."

He says that on most days and at their normal operating weight they see initial rates of climb of about 800-900 fpm.

Landing is yet another exercise which requires understanding the airplane's unique personality.

"We fly downwind at about 130 knots and 30". The flaps only have two positions, takeoff and landing. We put takeoff flaps in on downwind and full flaps on final. The flaps aren't very effective, so even a no-flap landing only requires an additional 10 knots. We fly final at 120 knots and bring it over the end of the runway at about 105 knots, which isn't very fast."

Erickson explains that during the entire landing he is concentrating on flying the airplane. He has both hands on the yoke and is calling out configuration and power changes to the co-pilot.

"When you are close to the ground, the co-pilot closes the throttle and you flair just like you're flying a Cub. A three-point landing is the best, but if it isn't quite there, it doesn't do anything. It just rolls along and, as it slows down, the tail comes down. It's fairly easy to steer while moving, but, as it slows down and your rudder authority dies out, you have to have good cross wind technique and use ailerons to help you steer it."

Once the airplane is on the ground, Erickson is emphatic about not doing anything but rolling straight ahead until completely stopped.

"You apply both brakes smoothly and bring the airplane to a stop. If you do that, it's not too bad. If you try to steer it and you're only doing 15 knots and think you'll turn off at an intersection, you'll lose it. It just can't be done."

Once stopped, however, there are still other systems to be considered.

"And then there's the problem of the generators. You have to set engines two and three at 1200 rpm to get those generators on line. They don't like to be run slow, so you leave one and four off and use the other engines to help steer.

It's seldom we see a warbird of any kind that hasn't had the nicks and scratches earned during a life time of service replaced with the sheen of a perfect restoration. In the act of restoration the in-service aura of a warbird is forever lost. It "feels" and smells different. The Amjet Shackleton, however, has that aura. It reeks of long nights out over the North Atlantic and it's radar seats look as if a tired operator just unstrapped after a long, grueling mission. With its nearly 40 years in harness barely behind it, the airplane not only presents a rare look at British technology in transition, but lets us see what a warbird looked like while it was still a warbird. This is an airplane that shouldn't be missed. As far as that goes, this is an airplane that's hard to miss.