We don't like to think about crashes. We'd like to think once we are off the ground, our flying machine will be 100% reliable and every landing will be that of a feather. That's the dream.

And then there is the reality. Gravity sometimes has a way of exerting its power in an effort to prove old man Newton is forever right.

But crashes don't always have to be fatal and serious injury doesn't have to be a forgone conclusion. It is tragic to see how many folks are involved in accidents that were not only survivable but which should have resulted in fairly minor injuries but didn't.

The extremely negative results of an unplanned collision with Planet Earth are sometimes the fault of poor crash survivability engineered into the airplane by the designer. However, the weak crash survivability of the basic design is often compounded by the builder not planning for close encounters of the worse kind and either doing things that violate common sense rules of crash survivability or not recognizing the weaknesses of the design and trying to work around them.

In addition, a lot of crashes could be survived if the pilot only recognized there are right and wrong ways to crash an airplane, be it an ultralight or a Mustang.

From the git-go it is obvious some crashes are not likely to be survived. Hit the ground vertically from 500 feet and nothing short of ten feet of engineered, high-density foam is going to save you. We aren't going to address that kind of situation.

First we're going to talk about the options the pilot has in orchestrating his own crash, then we'll talk about basic airframe considerations in designing for survivability and we'll wind up by addressing things the builder can do in building survivability into his airplane.

Most crashes are the result of either pilot error during landing or takeoff, or power failure. Seldom is the airplane totally out of control, which is another way of saying, it is still flying and the pilot has the final say as to how the airplane is going to impact. Granted, his options will ultimately give into gravity, but there are right and wrong ways of hitting the ground.

In the first place, forward motion isn't always the evil gremlin it is painted to be. Most injuries sustained during an accident are the result of vertical velocity and include spinal column damage. Sure, if running into a building or a tree, it would be nice to be slower, but, after a point, slower in an airplane never happens without the down component getting larger.

Every airplane has a best rate of descent glide speed which translates into the most ground covered in a forward direction for the least amount of altitude sacrificed; the most forward for the least down.

When the ground starts rushing

up at us in a crash situation we'd all like our airplane to assume

the glide characteristics of a parachute. In the worse sort of

way we want to get rid of that forward speed we know is causing

the trees to rush past at such a horrifying rate. Intellectually

we know the best glide speed is supposed to be the best of both

worlds, but its hard not to start cheating that nose up to get

rid of speed. However, if we give in, and the power plant is no

longer there to overcome the resulting increased drag, the airplane

has no choice but to give into gravity and let the airplane down

faster.

When the ground starts rushing

up at us in a crash situation we'd all like our airplane to assume

the glide characteristics of a parachute. In the worse sort of

way we want to get rid of that forward speed we know is causing

the trees to rush past at such a horrifying rate. Intellectually

we know the best glide speed is supposed to be the best of both

worlds, but its hard not to start cheating that nose up to get

rid of speed. However, if we give in, and the power plant is no

longer there to overcome the resulting increased drag, the airplane

has no choice but to give into gravity and let the airplane down

faster.

Many injuries are the result of getting the airplane too slow while still too far off the ground. The airplane didn't stall, but the nose was brought up while the airplane was too high and the vertical rate of descent had plenty of time to skyrocket. There is a lot of structure in an airplane to absorb forward impact, but very little that works in the vertical direction.

Rule one in crashing: Fight the urge to pull. Maintain best glide speed until flaring just before impact. Try to make the landing as nearly normal as possible.

Rule two: Use the airframe to absorb as much energy as possible.

Airframes are designed to fly, not crash, although a good designer gives some thought to the unthinkable. When thinking crash survivability he will be thinking in terms of energy absorption. He will be deciding how he can best design the airplane so energy is used up in crushing the airframe and ripping parts off, thereby reducing the energy level before it gets to the pilot?

But, the pilot can play a few energy absorbing tricks of his own and, in so doing, save his own hide.

Some of what we're about to say is controversial since every situation and every airplane presents a different set of circumstances to be countered. However, if the pilot is thinking in terms of letting the airframe absorb the initial impact and delaying the impact's arrival into the cockpit, he may be able to orchestrate a scenario that works in his particular situation.

For instance, wings are ready-made energy absorbers and, if it looks as if the landing site is so rough a straight-ahead landing can't help but result in total destruction, the pilot might think about finding something to use in tearing a wing or two off. For instance, the movie stunt of running between two trees is more than a stunt, since it eats up a lot of energy. Another is waiting until the very last second and slipping hard enough to impact on a wing tip when it is in the process of moving forward and letting the impact crush the wing.

Excuse us if we sound as if we're speaking to children when we say to do everything possible to keep the nose of the airplane from impacting a large immovable object head on. That sounds obvious, but often it doesn't occur to the pilot. They'll be in the flair and a big rock, tree or building suddenly looms ahead. Don't hit it head on! Stuff a wing into the ground. Slip. Turn. Do anything, but get the nose going in another direction so the impact isn't directed right into the cockpit.

If the airplane is still in the air, it is still flying. If it is still flying, the pilot still has some options, even if it is just bottoming the rudder at the last second.

There's always been a controversy around gear-up, gear-down off-airport landings. Again, it depends on the situation and the airplane. A tail dragger will often flip on its back before the gear tears off. Tri-gears, on the other hand, instantly turn into nose draggers on touch down, which burns off a lot of energy. A really tall tri-gear might turn turtle, but probably not.

Rule Three in crashing: Don't wait until it happens to plan out your actions.

The last thing that should go through a pilot's mind just before shoving the throttle forward on takeoff should be his emergency procedures including where and how he is going to crash the airplane when the engine quits at 50 feet off the end of the runway. It is absolutely essential the pilot know what he is going to do ahead of time because once the engine quits and panic starts nibbling away at the logic process, the brain becomes the least useful organ in the body. Emergency plans already have to be in place and ready to activate through instincts, since there is no way plans can be made with any degree of coherency on the way down.

Until very recently aircraft designers

actually didn't give much thought to how their aircraft structure

would reaction when crashing. Their job was to make them fly well.

Not make them crash well.

Until very recently aircraft designers

actually didn't give much thought to how their aircraft structure

would reaction when crashing. Their job was to make them fly well.

Not make them crash well.

Also, although the concept of energy absorbing structures is hardly a new idea, it wasn't considered, when designing aircraft until the last few years. Many designers still don't give it much thought.

Different types of structures react in different ways during a crash. Part of this is because of the difference in materials and the rest is the way the structure is designed.

The airframe is very much a reflection of the characteristics of the materials used in its construction. Wood, for instance, has ultimate and yield strengths close together, so, if a piece of wood is compressed, it does just fine until it starts to give, then it fails all at one time. Steel will bend a lot further and take a permanent set before it finally fails. Composite materials fall somewhere in-between, as does aluminum.

A classic example of the extreme variations in the way different materials react in the same structure, is the wooden Pietenpols versus the steel tube versions. On impact, the wood fuselages explode in a spray of splinters while the steel ones progressively bend and fail.

From an energy absorption point of view, what the pilot would love to see is a structure that gradually deforms, then progressively fails, never completely giving into the aggressive forces. The energy used to deform the structure is energy that won't find its way into the pilot.

Pure strength, however, isn't the answer. A structure can easily be too strong! A perfectly rigid structure is as bad as a flimsy one. A structure that is so strong it doesn't deform will pass all the impact energy directly to the pilot. Remember what has happened in Indy race cars in the last few years: The old front engine cars would hit the wall, flip end for end for hundreds of yards and come to rest with hardly a scratch on the hub caps. The driver, however, would be mush. He felt the energy exactly as if he hit with no race car between him and the wall. Today's cars spray parts every direction as they are scrubbed off against the wall and the energy is used up in tearing the car apart in a very specific manner. Today, after a horrific crash, the driver simply unstraps and hobbles on to his next product endorsement. Sometimes though, they do have to comb their hair.

Once a material is chosen, i.e. tubing, composite, etc., the way it is arranged in respect to the pilot also has great bearing on how the pilot is going to fair in an accident.

One of the deciding factors on pilot survivability is the so-called "crush distance." This is the amount of distance between the pilot and the first part of the airplane to impact the ground. Is the nose out there only a foot or is it hung way out there at three yards? Also figuring into that is what that distance includes. Is it a single tripod of aluminum tubing or is it a long steel cage with one of Lycoming's best on the end of a long mount. The more stuff there is to crush and the longer the distance, the better the pilot's chances.

What the pilot hopes for is a personal deceleration rate that occurs over a long enough distance that he won't get shredded. If he comes to a rapid halt in two feet, that's one thing. If he has ten feet to slow down in, that is a totally different situation.

There are a lot of designs out there in which the soles of the pilot's shoes mark the beginning of the deceleration distance and the crush space includes his ankles and femurs. In the situations where the pilot is the first part of the airplane to reach the accident, he is protecting the airplane with his body, not the other way around.

The pilot doesn't have to be sitting out in front of the airplane to be in a high risk situation. If he is hanging out the bottom, he absorbs most of the vertical energy component, after the gear has spread out of the way. Of course, his top mounted engine will survive beautifully because it is cushioned by all the structure collapsing under it. It is further cushioned by the pilot.

There is an erroneous assumption that because ultralights land slowly, they don't need as much crash protection. To a certain extent, this is absolutely the case since impact force varies as per the square of the speed. However, to say they don't need as much crash protection is another way of saying its okay to hit the wall stark naked because you are only traveling 30 mph, rather than 60 mph. There is no such thing as too much protection!

If ultralights were all constructed of the same material as their bigger brothers, they would indeed have plenty of protection because of their slower speeds and lighter weights. However, most also use much lighter material, i.e. aluminum tubes, which deflect much easier, thereby ablating less energy. However, that's not all bad. Those ultralights and very-lights where are correctly designed, do give fair crash survivability because their structure does slowly deform. Those which are not correctly designed (interrupted or incomplete triangulation, poorly designed fittings, etc.) always have a few structural points that fail immediately, causing the entire structure to collapse and absorb very little of the impact energy.

Of course, all the foregoing assumes the pilot is inside and protected by the structure, rather than the other way around.

Assuming the designer has done his part and the pilot his, the big question is whether the builder has done his best in making his airplane survivable in an accident.

Ignoring whether the structure is properly built (welds correct, rivets okay, etc.), it is entirely possible for a builder to build stuff into the flight deck that can make even a minor fender bender unsurvivable .

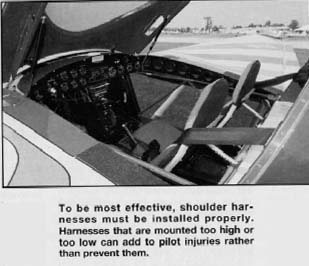

What you may ask can a pilot do to make sure his cockpit isn't downright dangerous? In the first place, he has to have a good set of belts, including shoulder harness, which are correctly mounted and of the configuration that works best for his specific application. For instance, if the seating position is flatter than normal, a seat belt and shoulder harness alone are of little use because the pilot will "submarine", or slide under the belt on impact. A crotch strap is needed in that situation.

It is also quite often that the shoulder harness is anchored either too high or too low. In a high anchored harness, the pilot is free to slouch forward and poke his face into anything he can reach. In a low anchored harness, part of the forward impact will be directed direction down through the shoulders which helps crush vertebrae. Belt manufacturers all supply installation drawings which show the correct angles and methods of attaching. Use the drawings. The manufacturers know what they are doing.

The bottoms of airplanes are notoriously short of crush distance, but NASA tests have shown only a few inches of the right mix of foams in the seat bottom will lower back damage dramatically. Even the most popular foam, like the multi-density Temper Foam, will held immensely.

Another space age material that might be incorporated into traditional designs is Kevlar. Since wood structures fraction into sharp pointed spears, most of which seem headed for the pilot's tender young body (this includes spars in biplanes, etc) it would be nice if there were something between the wood and the pilot to protect him. A layer of Kevlar bonded to the inside of the fuselage might help in that situation. So would a thin sheet, say .020", of aluminum. This might not solve the big problems but it would slow down splinter-access to the pilot.

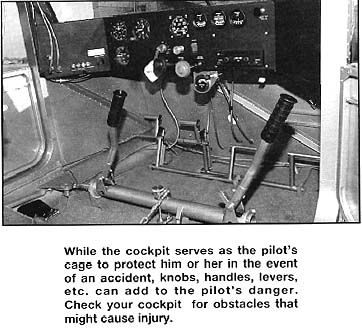

Then look around the cockpit itself. Make believe you are going to be hurled forward against the instrument panel. Will some part of the panel cut, jab or poke you? Does the glare shield have a stiff, sharp edge or is it blunt and easily deflected? Are there a bunch of knobs sticking out of the bottom of the panel just itching to get at your knees? Are there any sharp edges on the panel, control yokes or any of the various consoles? In an accident, everything becomes a potential surgical instrument.

What's under the panel down by your feet? If the firewall is slammed back hard, is there anything that can get your feet or legs? Should a valve or switch be moved to miss some important parts of your anatomy?

Ultralights may not have regular instrument panels but they often have gauges and switches hung from the overhead or shoehorned in under and around legs. Will they breakaway on impact or will they leave nasty gouges and cuts in your legs or head?

And speaking of heads, what about a helmet? It doesn't have to be one of those space age, visored jobs which cost a month's pay, but in some types of aircraft it makes sense to protect the old noggin. Those of us who cherish our brain cage wear them when motorcycling, why not when flying? Our bodies will eventually recover from having an aluminum tube jabbed through our stomach. Jab the same tube through our cerebral cortex and chances are we're out of chances.

Take a look at the structure. For instance, are the landing gear mount points aimed directly at your butt and is your only form of protection a canvas seat bottom? What about the edges of door frames or anything else that might wind up wrapped around you. Look for sharp edges and potential knife blades.

Ballistic chutes? To a lot of folks this seems like another way of saying you don't trust your airplane. But then, it is a machine and you are high enough to get hurt. So, why not? Some people have a nagging suspicion something is about to break or their two-stroke is about to quit (now, why would they think that?) and the ballistic chute gives them piece of mind. It also gives them a back door to use when everything else fails.

We're talking crash survivability here. We're talking about giving ourselves every chance possible when something serious goes wrong and there is absolutely no place for a "It can't happen to me" attitude. It can happen. If the airplane is always approached as if "it" is going to happen, then, at the very least, the pilot will be prepared. If he's not, he may wind up ruining his and his family's life simply because he was too complacent to go the extra step and prepare himself and his machine for an accident.

'Think there is nothing to worry about? Look carefully at your kids asleep in their beds and think again. You owe it to them to go over your airplane one more time with crash survivability in mind.